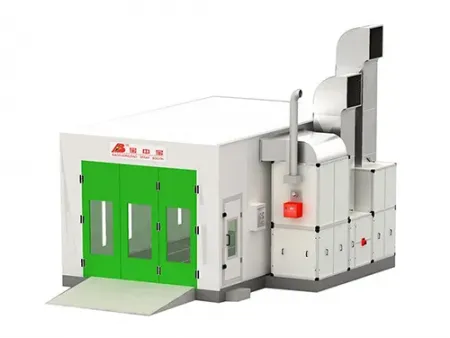

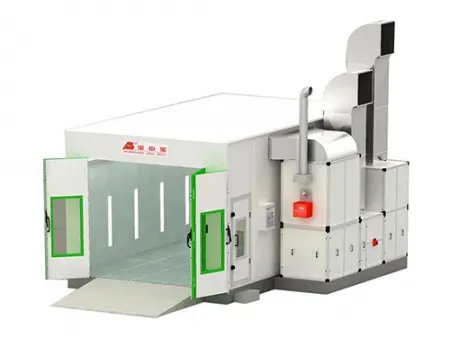

BZB-8500 Car Spray Booth

Request a Quote

Advantages

This BZB-8500 car spray booth is designed to cater for the actual needs of customers from all walks of life. It is appropriate for the vehicle repair factories and common car 4S shops within the countries and regions in demand for environmental protection.

Features

- The polystyrene heat-retaining board is 70mm thick. It offers wonderful thermal insulation effect. Additionally, it can enhance the strength and extend the service life.

- Three ramps are designed for the vehicles of various wheelbase sizes, which offer much convenience for the entry of cars.

- Moreover, our car spray booth is supplied with two 4kW supply fans, which give the supply air volume of up to 250,000m3/h. It also adopts an eco-friendly cabinet where there is a 7.5kW exhaust fan. Then, the air exhaust process is friendly to environment, and the air capacity can reach 20,000m3/h. Our fan also facilitates the discharging of paint mist and the filtration of exhaust gas. Both air inlet and outlet come with a manually adjustable air door, which can regulate the volume of supply and exhaust air at will, and also adjust both positive and negative pressure.

- The air supply and exhaust system is mounted with a stand-alone air inlet cabinet, providing sufficient internal circulation, fast heating rate, and ultra high energy efficiency.

- The furnace takes advantage of the pressure relief device for high safety.

- A 20N electric actuator is equipped for extremely strong power.

- Beyond that, this car spray booth adopts the side lights to increase the light intensity to 1000Lux. No ghosting is caused during the paint spraying operation.

Paint Booth & Finishing System for Your Applications

Configuration Table

| Outside dimension | Inside dimension | Front door dimension | Working door dimension |

| 7000*5560*3430mm(L*W*H) | 6900*4000*2650mm(L*W*H) | 3000*2600mm(W*H) | 650*1800mm(W*H) |

| Chamber System | 1. Our wall panel is the insertion type fire-resistant polystyrene insulation board. Its thickness is 70mm. 2. Around the door and chamber, there is the aluminum alloy framework. 3. At the top of our car spray booth, the steel-plate folded edge is sprayed with powder by adoption of compression molding technology. 4. The platform is constructed from high-quality galvanized steel plates and high-strength structural steel. Additionally, it is covered with galvanized grille. 5. Three ramps of 900mm wide are composed of anti-skid checkered plates. | ||

| Air Supply and Exhaust System | 1. Our car spray booth is supplied with two YDW-4.5AL1-4kw double-inlet centrifugal type supply fans with external rotor. The total supply air volume reaches 25,000m3/h. A set of YDW-5.6M-7.5kw centrifugal type exhaust fan with external rotor is installed with the air capacity of 20,000m3/h. 2. The fan cabin consists of the aluminum alloy profiles and coated steel plates. 3. The air is supplied from the back. Both air inlet and outlet are designed with the manually adjustable air vent. 4. The exhaust duct is composed of the high-quality galvanized steel sheets and professionally manufactured flanges. 5. The air velocity is 0.35m/s, and the air change ratio reaches 320 times per hour. | ||

| Purification System | 1. The intake-air primary filter is the exceptional-quality filter screen. It can effectively grab the particles with the diameter of over 10μm. 2. Our car spray booth utilizes the Italian-made filter screen as its high-efficiency top filter. It can take hold of the dust particles with the diameter of more than 4μm. 3. The floor filter adopts the glass fiber cotton imported from Italy. The TSP value is at most 1.4mg/m3. | ||

| Heating System | 1. The G20 type light-oil burner offers a heating value of 180,000kcal/kg. 2. The exchanger puts to use the supreme-quality SUS304 stainless steel by adoption of argon-arc welding technology. 3. A 20N electric actuator is imported from Switzerland with original packaging. It can realize the automatic changeover of spraying and curing. 4. The highest temperature reaches 80 degrees Celsius. The heating rate is 6-8min at a temperature of 20-60℃. The rate of oil consumption varies from 6kg to 8kg per unit. | ||

| Lighting System | 1. Side of the Ceiling: 32 pcs 18W LED tubes 2. Side of the Waist: 16pcs 18W LED tubes 3. Intensity of Illumination:1000Lux | ||

| Electric Control System | 1. A microcomputer program serves to control this system. The main circuit features multi-protection. The whole working process and fault conditions can be automatically displayed. 2. This control system is designed with the lighting switch, temperature and time settings, room-temperature or constant-temperature spraying, curing switch, emergency stop switch, failure alarm, time and counter, among others. | ||

| Exhaust Gas Treatment | The activated carbon is used to filter the exhaust gas. The exhaust emissions can reach the GB16297-1996 national standard. (in compliance with the integrated emission standard of air pollutants) | ||

| Others | 1. The closed type oil tank and tool cabinet is able to store paint and tools. 2. The track frame is constructed from superior-quality steel, which allows small parts to be sprayed conveniently. | ||

Please click the to get more information about heating systems.

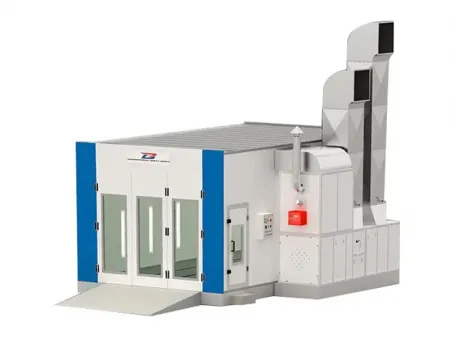

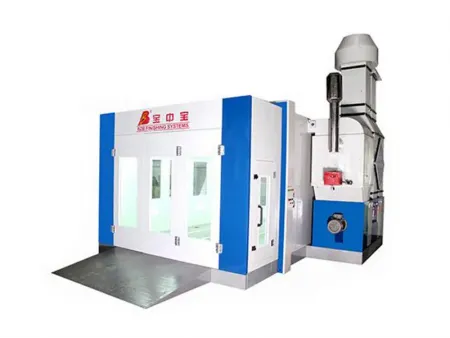

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos