Servo Driven Premade Pouch Packaging Machine, 1-Nozzle Filling

The servo driven premade pouch packaging machines are developed for premade pouch applications that require accurate dosing of powder and granular materials. The system integrates a high-precision powder filling unit, allowing material to be filled into pouches either sequentially or in coordination, depending on product formulation and process requirements.

Servo-driven motion control ensures stable pouch handling, precise filling, and consistent sealing performance. It is suitable for products that involve single or mixed material forms, that require dosing precision and repeatability. They are widely applied in the packaging of premium seasonings, compound powdered beverages, functional powders, pet food, and pharmaceutical intermediates, where production standards and process control are critical.

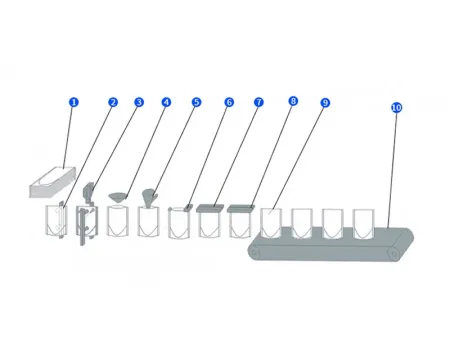

- Pouch loading unit

- Pouch pick-up unit

- Pouch opening unit

- Air blowing unit

- Filling unit

- Pouch shaping unit

- Heat sealing unit

- Cooling sealing unit

- Finished pouch

| Model | | | |

| Pouch parameters | Min. pouch size (W × H) | 80mm×130mm | 90mm×130mm |

| Max. pouch size (W × H) | 240mm×350mm | 280mm×400mm | |

| Max. filling volume (stand-up pouch) | 2000ml | 3000ml | |

| Packaging speed | ≤45 packs/min | ≤40 packs/min | |

| Equipment specifications | Dimensions (L × W × H) | 2880mm×1100mm×1400mm | 3200mm×1100mm×1500mm |

| Net weight | 1400kg | 1500kg | |

| Operating conditions | Operating temperature | -10℃ to +55℃ | -10℃ to +55℃ |

| Relative humidity (non-condensing) | ≤85% | ≤85% | |

| Power supply | AC380V, 50Hz | AC380V, 50Hz | |

| Operating air pressure | 0.6Mpa | 0.6Mpa | |

| Air consumption | 350L/min | 350L/min | |

| Motor power | 5.5Kw | 5.5Kw | |

Zipper opening

Pouch hole punching

- Sombrero hole (butterfly hole)

- Round hole

- Special-shape punching

- Arc hole / Curved slot hole

- Euro hole

Coding options

- Hot stamp coding

- Inkjet printing

- Laser marking

Sealing patterns

- Grid pattern

- Dotted pattern

- Plain/flat pattern

- Vertical rib pattern

A nutraceutical manufacturer based in the Netherlands introduced the 280NG servo driven premade pouch packaging machine to support protein powder packaging. The system handles product weights ranging from 100g to 2kg and is configured for zipper stand-up pouch production, meeting both functional packaging requirements and market presentation needs.