Single Hole Spinning Spinneret for Manufacturing Dual Layer Composite Hollow Fiber Membrane

1. Year: 2017

2. Country: Singapore

3. Customer: Century water

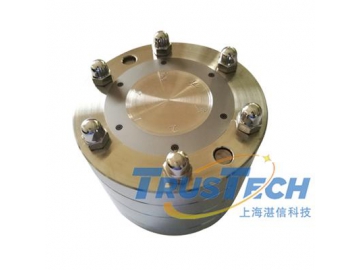

4. Product: Single hole spinning spinneret for manufacturing dual layer composite hollow fiber membrane

5. Processing type: NIPS

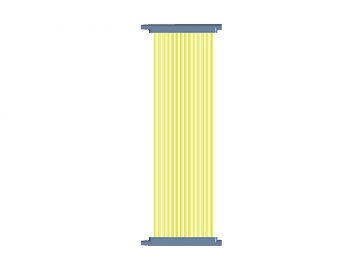

6. Application: Environment protection, water purification

7. Specification: 1.6/1.3/1.1/0.6/0.4

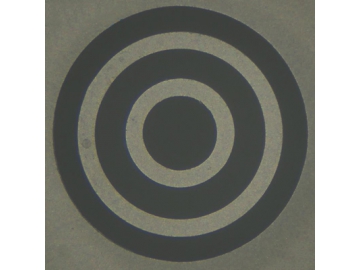

8. Manufacturing capability: 1.600±0.002mm, 1.300±0.002mm, 1.100±0.004mm, 0.600±0.002mm, 0.400±0.004mm;assembly concentricity 0.003mm.

9. Spinneret material: Stainless steel

10. Applying material: PVDF (Polyvinylidene Fluoride)

In 2017, a customer requested a single hole spinning spinneret for manufacturing dual layer composite hollow fiber membrane to make high-separation-performance membranes with high flux and high pollution protective separation function.

Applicable material

PVDF (Polyvinylidene Fluoride), CA (cellulose acetate), PVC (Polyvinyl chloride), PES (Polyethersulfone), PSF/PSU (Polysulfone), PA (Nylon, Polyamide), PAN (polyacrylonitrile)

Trustech is a leading polymer fiber spinning spinneret manufacturer, by combined with advanced technology of fiber spinning process and equipment from Germany we can fabricate high quality spinneret, we can offer spinnerets used wet spinning, dry spinning, melt spinning for different fiber spinning process users, we have had clients who used our spinnerets to produce hollow fiber membrane for different filtration applications.

Index

wet spinning, melt spinning, drying spinning, gel spinning, spinning process