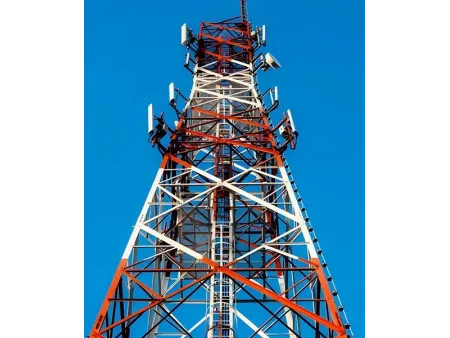

4-Legged Angular Steel Communication Tower

Self-supporting towers made of angular steel profile sections for use as telecommunication towers with heights ranging from 5 to 110 meters

4-legged angular steel towers are formed by four steel angle columns connected at the joints with bolts to create a stable and rigid lattice structure. The lattice design spreads the load evenly through the telecom tower, which helps keep the whole structure stable in real working conditions. This balance between strength and cost is one of the reasons why this type of tower is widely used in telecommunication projects.

- Design Standards ANSI/TIA-222-G/H/F; EN 1991-1-4; EN 1993-3-1

- Height Range 5–110 m, customizable to project needs

- Design Wind Speed Up to 300 km/h, adjusted according to site conditions

- Surface Treatment Hot-dip galvanized; Painting

- Main Structure

Four galvanized steel angle columns (legs) (Q355B / Q420B) are arranged in a square layout to form the main load-bearing structure. The top section is connected through horizontal beams and fitted with a lightning rod. - Bracing System

Diagonal bracing between the legs forms a lattice truss system that provides strong resistance to bending and torsion, while keeping wind resistance at a low level. - Connection Method

The entire structure uses bolted connections, mainly with M20–M24 bolts tightened to a torque of at least 400 N·m. This connection method makes both transportation and on-site assembly much more practical.

Typical Installation Environments

Open, wide areas with steady ground and lower wind exposure are recommended, such as suburban and rural locations. Since these areas usually have stable ground and open surroundings, foundation construction is more secure, and the tower can operate steadily over the long term.

| Product | Telecommunication tower |

| Tower Type | Self-Supporting Tower |

| Design Standards | ANSI/TIA-222-G/H/F; EN 1991-1-4; EN 1993-3-1 |

| Quality Certification | ISO 9001: 2015; COC; Third Party Inspection Report (SGS, BV) |

| Bolts & Fasteners | Grades 8.8 / 6.8 / 4.8; ASTM A325; DIN 7990, DIN 931, DIN 933; ISO 4032, ISO 4034 |

| Main Material | Angle steel |

| Height Range | 5–110 m, customizable to project needs |

| Design Wind Speed | Up to 300 km/h, adjusted according to site conditions |

| Surface Treatment | Hot-dip galvanized; Painting |

| Galvanizing Standard | ASTM A123 / ISO 1461 |

| Expected Service Life | More than 20 years |

| Color Options | Silver (galvanized) or painted finish, RAL color system, customizable |

| Seismic Resistance | Up to 8° seismic intensity |

| Operating Temperature Range | -35°C to 45°C |

| Working & Rest Platforms | 1–3 pcs |

| Antenna Brackets | 3–18 pcs |

| Microwave Dish Brackets | 3–18 pcs |

| Main Features | Stable structure, clean appearance, reliable long-term performance |

| Certification Standard | ||

| Design Standards |

| |

| Structural Steel | ||

| Grade | Mild Steel | High Tensile Steel |

| GB/T 700 – Q235B, Q235C, Q235D | GB/T 1591 – Q355B, Q355C, Q355D, Q420B | |

| ASTM A36 | ASTM A572 Gr.50 | |

| EN 10025 – S235JR, S235J0, S235J2 | EN 10025 – S355JR, S355J0, S355J2 | |

| Design Wind Speed | Up to 300 km/h | |

| Allowable deflection | 0.5–1.0° @ operational speed | |

| Tensile strength (MPa) | 360–510 | 470–630 |

| Yield strength (t ≤ 16 mm) (MPa) | 235 | 355 / 420 |

| Elongation (%) | 20 | 24 |

| Impact strength KV (J) | 27 (20°C) - Q235B (S235JR) | 27 (20°C) - Q355B (S355JR) |

| 27 (0°C) - Q235C (S235J0) | 27 (0°C) - Q355C (S355J0) | |

| 27 (-20°C) - Q235D (S235J2) | 27 (-20°C) - Q355D (S355J2) | |

| Bolts & Nuts | ||

| Grade | Grade 4.8, 6.8, 8.8 | |

| Standards for mechanical properties | ||

| Bolts | ISO 898-1 | |

| Nuts | ISO 898-2 | |

| Washers | ISO 7089 / DIN 125 / DIN 9021 | |

| Standards for dimensions | ||

| Bolts (dimensions) | DIN 7990, DIN 931, DIN 933 | |

| Nuts (dimensions) | ISO 4032, ISO 4034 | |

| Washers (dimensions) | DIN 7989, DIN 127B, ISO 7091 | |

| Welding | ||

| Method | CO₂ Shielded Arc Welding & Submerged Arc Welding (SAW) | |

| Standard | AWS D1.1 | |

| Galvanizing | ||

| Galvanization standard of steel sections | ISO 1461 or ASTM A123/A123M | |

| Galvanization standard of bolts and nuts | ISO 1461 or ASTM A153/A153M | |

Main Components

- Anchor Bolts

- Antenna Mounting Bracket

- Copper Grounding Components

- Connection Plates

- Antenna Mast

Optional Components

- Communication Tower Bolts

- Aviation Obstruction Light

- Climbing Ladder

- Copper Lightning Rod

- Grating Platform and Mesh Platform

We provide full technical guidance and carry out construction based on the approved drawings. If any questions arise, we are always available to assist.

Structural Stability

The four-legged structure spreads the load from all directions, which keeps the tower steady under wind and seismic action. Due to the truss layout, wind loads are shared about 20% more efficiently. With the legs reinforced, the telecom tower is capable of withstanding about 30% more compressive load and around 25% more tensile load during operation.

Material Durability

The 4-legged communication tower is built with hot-dip galvanized steel angles using Q235B, Q355B, and Q420B grades as the main structural material. These types of steel provide yield strength of ≥235 MPa, ≥355 MPa, and ≥420 MPa, with tensile strength reaching 370–500 MPa, 470–630 MPa, and 520–680 MPa. Due to the outstanding features of these materials, the 4-legged towers can easily handle winds above Force 12 and meet earthquake resistance requirements above Grade 8, which makes it reliable for long-term outdoor use.

Cost Efficiency and Easy Maintenance

The construction period of the 4-legged angular steel tower is relatively short, and steel angles are a cost-effective material. Its durable angular steel structure means less maintenance and lower operating costs over time.

Flexible Installation

4-legged angular steel communication tower is put together with bolted connections, which makes installation on site much easier. During construction, the height or angle can be adjusted according to the terrain, allowing the team to work more comfortably under real site conditions.

Wide Site Adaptability

Whether installed in mountain areas, flat land, or dense urban zones with limited space, the angular steel tower can be adapted through structural adjustments to suit different terrains.

- 50m 4-Legged Angular Steel Tower

- 40m 4-Legged Angular Steel Tower

- 60m 4-Legged Angular Steel Tower

Laser Cutting

Laser cutting is used to shape the steel components through focused beam cutting and assisted gas removal. The process offers fast cutting speed and high dimensional accuracy (up to ±0.05 mm), while keeping heat impact to a minimum. This reduces the risk of deformation and results in clean, well-defined edges.

CNC Punching and Shearing

Steel angles are processed through CNC-controlled punching and shearing lines. Automatic feeding, positioning, punching, and cutting are all integrated into the process, keeping production running smoothly and efficiently. Precise CNC positioning keeps quality consistent, even when working with more complex parts.

Hot-Dip Galvanizing and Surface Protection

The tower is protected with hot-dip galvanizing as the main anti-corrosion treatment, along with an extra plastic coating for added protection. The zinc layer protects the steel from rust and adds strength, while the coating gives extra insulation and surface protection. This combined treatment allows the tower to maintain reliable performance for over 20 years and adapt well to harsh environments such as high and low temperatures, coastal areas, and mountainous regions.