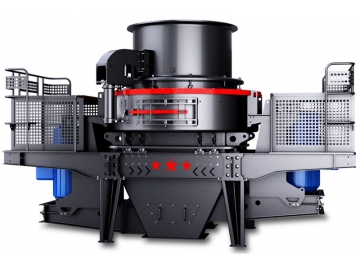

Vertical Shaft Impact Crusher

VSI series vertical shaft impact crusher is the newest type of sand making machine produced by Dingbo, it is 50% energy saving than traditional sand maker. All kinds of rock, sand, gravel can be made into building sand by our crusher, the finished sand has uniform particle size and high compressive strength, that is more suitable for the construction requirements and also can improve the building quality. This crushing machine has advantages of reliable performance, reasonable design, convenient operation and high efficiency. It can provide high quality gravel aggregate for highway, high-speed railway, high-rise building, municipal engineering, hydropower dam construction, concrete mixing station. It is an ideal equipment for making artificial sand and building stone.

Working Principle

The material is fed into the hopper the vertical shaft impact crusher, and entered high-speed rotation wheel through the center of the feeding hole, the material is rapidly accelerated inside the wheel, and then thrown out at a high speed from the wheel. First, the material will be impacted by each other, and then impacted on the lining or block, after that it will be impacted to the top of the crushing chamber, and its movement direction will be changed, at the same time it will be continuously impacted with the material from the impeller passage. So that, the material will be subjected to at least two times or multiple times of impact, friction and grinding in crushing chamber. The crushed material will be discharged from the bottom of the discharge hole.

Application

VSI series crushers are widely used in crushing applications for nonmetal mines, concrete, fireproof materials, abrasive fillers, construction aggregate, sand and so on. It is an indispensable machine in the sand making industry and it is also an ideal truing machine for mining and construction industries.

Features

1.Large quantity and high yield

Production output is increased by 30% compared to traditional equipment at 50-500t/h

2.Low parts consumption

Designed with the optimal angle for the crushing capacity reduces friction and wear on consumable parts. Operation costs can be lowered by 30%

3.Grain shape options

Products are formed into cubes, the grain shape is consistent with adjustable fineness. Suitable for artificial sand.

4.Easy to maintain hydraulic device

Hydraulically opened crushing cavity to allow for simple internal maintenance.

5.Automatic detection

If a problem is detected during operation the device has an auto shutdown and an alarm.

6.Thin oil lubrication

Double pump oil supply that transports oil for cooling and hot oil.

7.Simple installation

Lightweight structure facilitates easy installation.

8.Hydraulic Pressure Jack Device

This series impact crusher employs a hydraulic pressure jack device that is convenient to use and timesaving.

| Model | Feed at center & sides | Feed at center | Soft Material | Hard Material | REV (r/min) | Power (kw) | Motor Model | Machine Size (mm) |

| Capacity (t/h) | Max.Feeding (mm) | |||||||

| 120-180 | 60-90 | 35 | 30 | 1700-1890 | 4-55×2 | Y250M-4/55 | 4100×2250×2258 | |

| 200-260 | 100-130 | 40 | 35 | 1520-1690 | 4-90×2 | Y280M-4/90 | 4140×2280×2425 | |

| 300-380 | 150-190 | 45 | 40 | 1360-1510 | 4-132×2 | Y315M-4/132 | 4560×2450×2780 | |

| 450-520 | 225-260 | 50 | 45 | 1180-1310 | 4-200×2 | Y315L2-4/200 | 5100×2690×3200 | |