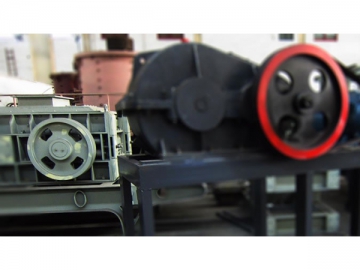

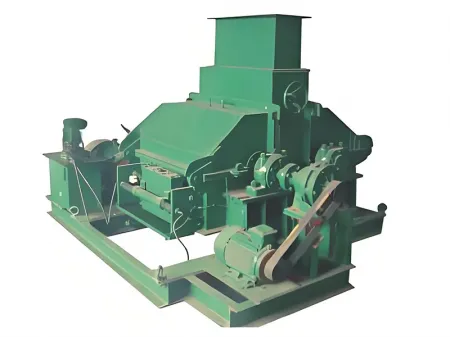

Roller Crusher

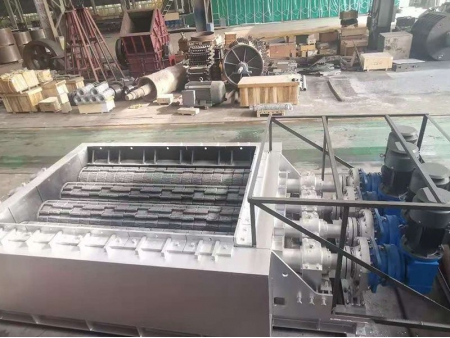

Roller crusher is designed on the basis of the American advanced technology. It has the advantages of small size, large crushing ratio, low noise, simple structure, and easy maintenance. It is applicable to coal, metallurgy, mining, chemical, building materials and other industries, and also suitable for large coal mine and coal plant. Hydraulic couplings are used for connecting motor and reducer, which can prevent power overload. The distance between rollers can be adjusted, and the roller bearings can be centralized lubrication. Tooth profile with optimal design can make the particle size uniformly.

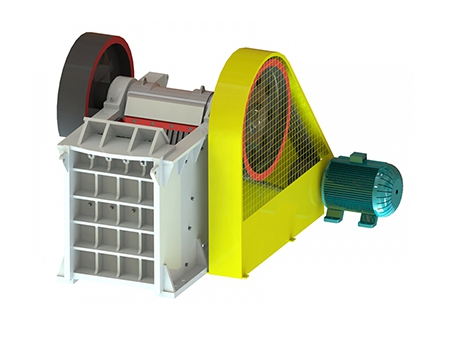

Working Principle

The roller crusher is divided according to its specification. The discharging granularity is adjusted by wedge or spacer between two rollers, this adjustable device is equipped with a adjusting bolt on the top of it, when pulling up the adjusting bolt, the wedge will make the moveable roller moving to the fixed roller, the gap between each rollers becomes larger, and the discharging granularity becomes larger. When pulling down the adjusting bolt, the moveable roller will be pressed by spring, and the gap between each rollers becomes smaller, and the discharging granularity becomes smaller.

Features

1. Compared with grinding machine, the roller crusher has compact structure, light weight, small size, and low cost.

2. This crushing machine features of simple structure, small floor area, easy operation and maintenance.

3. Equipped with dust shield, our roller crusher has good seal performance, which can avoid splashing of fine material after crushing, with less dust and low noise.

| Model | Feeding Size (mm) | Output Size (mm) | Capacity (t/h) | Motor Power (kw) | Weight (t) | Overall Dimension (mm) |

| <16 | ≤2-8 | 5-10 | 2×5.5 | 1.3 | 2110×870×810 | |

| <36 | ≤2-20 | 10-20 | 2×15 | 3.9 | 3510×1420×1030 | |

| <40 | ≤2-25 | 10-40 | 2×18.5 | 9.5 | 4210×1630×1260 | |

| <40 | ≤2-25 | 12-45 | 2×22 | 10.8 | 4505×1780×1320 | |

| <40 | ≤3-30 | 20-65 | 2×30 | 14.9 | 5310×2175×1595 | |

| <40 | ≤3-35 | 35-80 | 2×37 | 25.5 | 6290×2270×1870 | |

| <40 | ≤3-45 | 50-120 | 2×75 | 33.7 | 7460×2410×2290 | |

| <40 | ≤3-50 | 60-140 | 2×90 | 41.2 | 8220×2680×2475 |

Note: all technical specification are based on relevant standards, additional requirements can be negotiated upon order placement.