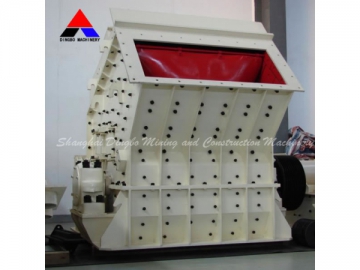

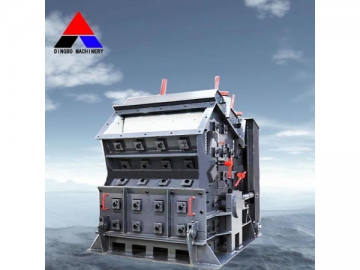

Impact Crusher

Dingbo has specially developed impact crusher to meet the requirement of crushing micro carbon ferrochromium with high strength and high hardness for the industries such as metallurgy, mine, and construction. Our crusher is widely used for crushing all kinds of ores and bulk materials with medium particle size in mining, building materials, roads, railways, water conservancy and chemical industries.

Working Principle

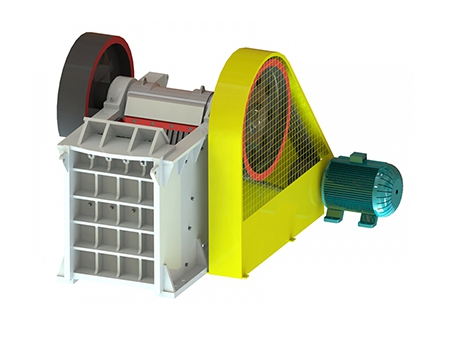

This kind of crushing machine uses impact force to crush materials. Rotor is rotating at a high speed in the motor, the materials are impacted and crushed by the hammer on the rotor. The crushed materials are impacted again by liner plate, and then discharged. Particle size and shape can be changed by adjusting the clearance between impact plate and rotor frame.

Features

1. High efficiency, energy saving, wear resistance and crush resistance. This impact crusher has large crushing ratio and high crushing efficiency, its rotor has large rotary inertia. It adopts high chromium hammer which is anti impact and anti wear, so that the service life of wearing part is prolonged.

2. Particle size and shape are adjustable, the discharge adjusting device is on the top of the crusher, which can be used for adjusting the clearance between impact plate and hammer, and controlling the particle size. The finished product is in the shape of cubic without tension crack, which can meet all grade standards of gravel aggregate.

3. Simple structure and easy maintenance. Our crushing machine is composed of housing, rotor and impact plate. The machine frame can be opened quickly by lifting device, which is easy to replace and maintain the accessories. The rotor and main shaft is connected by expanding sleeves without key joints, that is convenient for maintenance, economical and reliable.

| Model | Rotor Φ×L (mm) | Feed Opening (mm) | Max Feeding (mm) | Capacity (t/h) | Power (kw) | Motor Model | Machine Size (mm) |

| Φ1000×1050 | 400×1080 | 350 | 50-80 | 6-75 | Y280S-6/75 | 2455×2086×2800 | |

| Φ1250×1050 | 400×1080 | 350 | 60-120 | 6-110 | Y315L1-6/110 | 2590×2050×2810 | |

| Φ1250×1400 | 400×1430 | 350 | 80-160 | 6-132 | Y315L2-6/132 | 2590×2400×2810 | |

| Φ1320×1500 | 860×1520 | 350 | 120-260 | 6-200 | Y355M3-6/200 | 2930×2760×3050 |

Note: all technical specification are based on relevant standards, additional requirements can be negotiated upon order placement.