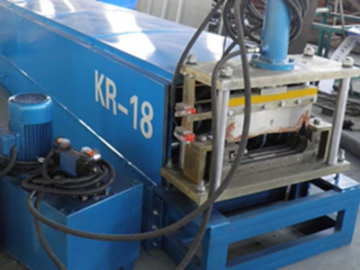

Roll Shutters Forming Machine

As an ISO9001 certified roll shutters forming machine manufacturer, we are able to provide customers with high quality forming machines. Our dedicated technical team, extensive experience and cooperative relationships with famous universities in China enable us to keep our technology current and constantly introduce new products to the market.

The product shown on this page is our CE compliant roll shutters forming machine, which features high speed, high automation and great reliability. This machine is composed of decoiler, sheet guiding equipment, roll forming section, cutter, supporter, hydraulic system and control system. The roof and wall produced by it are aesthetic, durable and easy to use, with even ripples.

This type of forming machine comes in two models, whose main technical parameters are as follows

Roll Shutters Forming Machine,

| Thickness | 0.6-1.2mm |

| Forming step | 13 |

| Main motor | 5.5KW |

| Forming spec. | HZ-180,HZ-128 |

| Cutting | Hydraulic cutting |

| Main motor | 3KW |

Roll Shutters Forming Machine,

| Thickness | 0.8-2.0mm |

| Forming step | 14 |

| Main motor | 7.5KW |

| Forming spec. | HZ-30,HZ-60 |

| Cutting | Hydraulic cutting |

| Main motor | 3KW |

Rolling Shutter Forming Machine,

(One machine for only one size)

Uncoiler: 2 tons

Polyurethane foaming machine

Servo flying saw

Mechanical punching system

PLC automatic control system

Run-out table

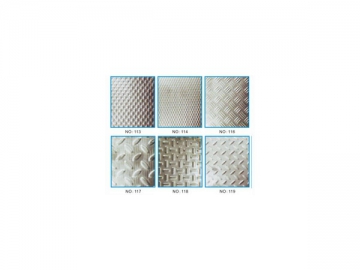

Material: Aluminum sheet

Thickness: 0.22-0.35mm

Width: 127mm

Drive type: Gear with universal joint transmission system

Forming steps: 37

Main power: 11KW

Forming Spec.: HZ-39/42

Speed of Italian machine (high speed): 20-30m/min

Speed of Chinese machine (normal speed): 12-18m/min

Note: one machine can only produce slats in one size.

Processing Process

Uncoiler---Feeding guide---Roll forming rail---Preheating---PU foaming---Heat preservation---Roll forming---Levelling---Servo flying saw for cut off --- Conveying platform ---Mechanical punching---Run-out table

Rolling Shutter Forming Machine,

Uncoiler: 2 tons

Polyurethane foaming machine (SAIP Italy or China brand)

Servo flying saw

Mechanical punching system

PLC automatic control system

Run-out table

Material: Aluminum sheet

Thickness: 0.28-0.35mm

Width: 166mm

Drive type: Gear box with universal joint transmission system

Forming steps: 37

Main power: 11KW

Forming Spec.: HZ-55

Speed of Italian machine (high speed): 20-30m/min

Speed of Chinese machine (normal speed): 12-18m/min

Processing Process

Uncoiler---Feeding guide---Roll forming rail---Preheating---PU foaming---Heat preservation---Roll forming---Levelling---Servo flying saw for cut off --- Conveying platform ---Mechanical punching---Run-out table

Rolling Shutter Forming Machine,

Uncoiler: 2 tons

Polyurethane foaming machine

Servo flying saw

PLC automatic control system

Run-out table

Material: Aluminum sheet/ Colored steel sheet

Thickness: 0.27-0.5mm

Width (HZ-77): 229mm

Width (HZ-90): 313mm

Drive type: Gear box with universal joint transmission system

Forming steps: 37

Main power: 11KW

Working speed: 10-15m/min

Forming Spec.: HZ-77/90

Processing Process

Uncoiler---Feeding guide---Roll forming rail---Preheating---PU foaming---Heat preservation---Roll forming---Levelling---Servo flying saw for cut off ---Turn-out table

Uncoiler: 2 tons

Polyurethane foaming machine

Cutting machine: Flying saw

PLC automatic control system

Run-out table

Material: Aluminum sheet/ Colored steel sheet

Thickness: 0.7-0.8mm

Width (HZ-135): 400mm

Width (HZ-185): 500mm

Width (HZ-222): 615mm

Drive type: Chain drive

Forming steps: 44/46

Main power: 15KW

Working speed: 8-10m/min

Forming Spec.: HZ-135/185/222

Processing Process

Uncoiler---Feeding guide---Roll forming rail---Preheating---PU foaming---Curing---Heat insulation conveying platform---Pneumatic cutting--- Turn-out table

In addition to roll shutters forming machine, we also offer other types of forming machine, like tile roof forming machine, keel forming machine, Z shape forming machine, and more, which are very popular with customers from Britain, Spain, Portugal, and countries in Africa and the Middle East.

We are looking forward to working with customers worldwide. Please contact our sales team for more information.