Security Door Forming Machine

Security doors can not only provide protection for homeowners, but also add a touch of elegance to a home and raise the value of the home. We are a professional security door forming machine manufacturer in China. With years of experience in the field, we can provide customers with quality safety door frame forming machine, multiply security door hot press gluing machine, 3 inch, 6 inch jamb roll forming machine to customers all over the world.

Thanks to our continued focus on product improvement, our security door forming equipment is reliable, durable, energy efficient, easy to operate and maintain. To assist our customers in choosing the right product, here we give them the detailed specifications of our products

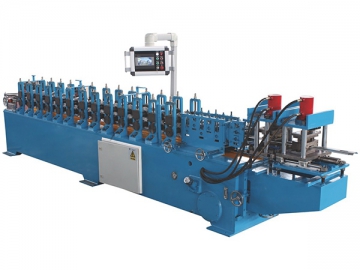

Safety Door Frame Forming Machine

| Thickness | 0.8mm-1.2mm |

| Width of material | 178mm-203mm |

| Motor power | 15kw |

| Hydraulic cutting | Hydraulic power |

| Stands | 20 |

Safety Door Frame Forming Machine, HZ-200

| Thickness | 0.8mm-1.8mm |

| Width of material | 260mm-530mm |

| Length of single piece | 800mm-6000mm |

| Motor power | 7.5kw |

| Production speed | (3-6)m/min |

| Stands | 20 |

| Main application | Safety door frame |

Safety Door Forming Machine, HZ-400

| Thickness | 0.8mm-1.8mm |

| Width of material | 200mm-380mm |

| Motor power | 15kw |

| Length of single piece | 1000mm-6000mm |

| Production speed | (3-6)m/min |

| Main application | Safety door frame |

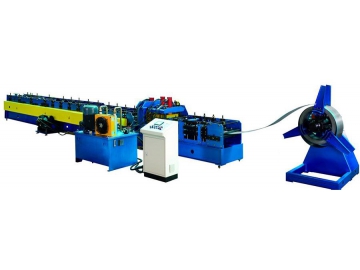

3 Inch Door Jamb Roll Forming Machine

| Material thickness | 0.8mm |

| Material width | 178mm-203mm |

| Effective width | 75mm-100mm |

| Forming steps | 20 |

| Motor power | 15kw |

| Main application | Single-side door jamb |

6 Inch Door Jamb Roll Forming Machine

| Material thickness | 0.8mm |

| Material width | 279mm-304mm |

| Effective width | 127mm-152mm |

| Forming steps | 20 |

| Motor power | 15kw |

| Main application | Double-side door jamb |

Multiply Security Door Hot Press Gluing Machine

HZ-80 Multiply Security Door Hot Press Gluing Machine

| Gluing machine | 10 layers |

| Overall dimensions of main frame | 2860*1260*2010mm |

| Weight of main frame | 12T |

| Dimensions of pressure plate | 40*1000*2200mm |

| Interlayer space | 110m |

| Stroke of oil cylinder | 550m |

| Working pressure | (6-10)T |

| Working pressure of hydraulic system | 30kg/cm2 |

| Temperature of press plate | 85℃ |

| Time of pressing | 15-30min |

| Heat conduction meson | hot water, steam, heat conduction oil |

| Wearing part | Sealing ring |

If you are looking for roll shutter forming machine, tile roof forming machine, or garage door forming machine, we can also help you with your needs. In order to offer customers superior quality products, we utilize CNC lathe, adopt COPRA design software from Germany, and adhere to strict requirements for every aspect of production, from the selection of raw materials to the final inspections of all finished products. As a result of our efforts, our products are high quality, CE compliant, and we are ISO9001 certified.

If you would like more information, please don't hesitate to contact us!