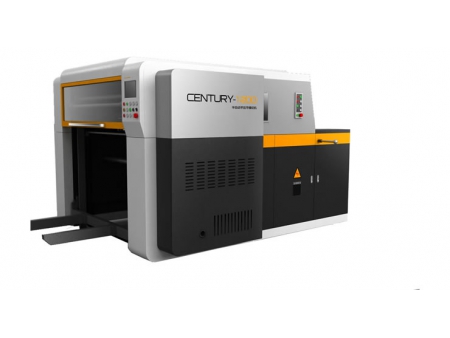

Semi-Automatic Flatbed Die Cutter, MWB-E Series

When compared to hand platen type die cutting machines, Century's MWB E Series semi-automatic die cutting machine has been improved on the following features:

1.Higher machine speed of 3,000 sph (sheets per hour).

2.Latest PLC technology

3.Automatic paper collection

4.Malfunction detection device

5.Safe machine operation for operators

The semi-automatic die cutter is suitable for packaging factories with limited work space and are applicable to corrugated board and paper board conversion.

There are four models under this series: MWB 1100E, MWB 1200E, MWB 1300E, and MWB 1450E.

1.Feeding Section

Advanced gripper bars and an open gripper feeding ensure a smooth feeding of the paper for multiple types of corrugated boards.

A side and front positioning system ensure the die cutting precision.

2.Die Cutting Section

A pneumatic push button die-chase locking mechanism ensures safe and operator friendly changing of the die-cutting plate.

The die cutting section uses the internationally known brands for the bearings and electronic components for precise control of the die cutting process.

3.Delivery Section

A cylinder motor driven delivery section ensures a smooth delivery.

4.Electrical Control Section

The electrical control section uses components from internationally known brands for a better performance, and quick, local, after-sales service and maintenance.

Siemen's latest PLC technology is used to guarantee safe and trouble free machine running.

This die cutter is also equipped with various safety protection devices. The machine will alarm and stop automatically when problems arise.

5.Main Drive Chain

A heavy load and highly precise chain achieves a high tensile strength and wear resistance.

6.Main Driving System

The main driving system adopts mono-block casting chassis to reduce the vibration and achieve a more stable performance, extending machine service life.

Deepened oil tank to make part of worm wheel working under lubrication oil for better lubrication

| Type NO. | |

| Maximum paper size | 1110*800mm |

| Minimum paper size | 400*380mm |

| Maximum cutting size | 1080*780mm |

| Maximum cutting pressure | 200 Tons |

| Stock range | Corrugated board: 1-7mm |

| Die-cutting precision | ±0.5mm |

| Maximum speed | 3000 s/h |

| Height of cutting rules | 23.8mm |

| Pressure adjusting range | ±1mm |

| Minimum gripper margin | 10mm |

| Inner chase size | 1110*780mm |

| Total power | 13.27KW |

| Machine's dimension(mm) | 3638*2926*1855 |

| Weight | 9 Tons |

| Type NO. | |

| Maximum paper size | 1200*820mm |

| Minimum paper size | 450*400mm |

| Maximum cutting size | 1180*800mm |

| Maximum cutting pressure | 200 Tons |

| Stock range | Corrugated board: 1-7mm |

| Die-cutting precision | ±0.5mm |

| Maximum speed | 3000 s/h |

| Height of cutting rules | 23.8mm |

| Pressure adjusting range | ±1mm |

| Minimum gripper margin | 10mm |

| Inner chase size | 1210*880mm |

| Total power | 13.27KW |

| Machine's dimension(mm) | 3664*3029*1861 |

| Weight | 10 Tons |

| Type NO. | |

| Maximum paper size | 1300*920mm |

| Minimum paper size | 550*480mm |

| Maximum cutting size | 1300*900mm |

| Maximum cutting pressure | 250 Tons |

| Stock range | Corrugated board: 1-7mm |

| Die-cutting precision | ±0.5mm |

| Maximum speed | 3000 s/h |

| Height of cutting rules | 23.8mm |

| Pressure adjusting range | ±1mm |

| Minimum gripper margin | 10mm |

| Inner chase size | 1330*920mm |

| Total power | 16.77KW |

| Machine's dimension(mm) | 4058*3249*1940 |

| Weight | 11 Tons |

| Type NO. | |

| Maximum paper size | 1480*1080mm |

| Minimum paper size | 550*480mm |

| Maximum cutting size | 1450*1050mm |

| Maximum cutting pressure | 300 Tons |

| Stock range | Corrugated board:1-7mm |

| Die-cutting precision | ±0.5mm |

| Maximum speed | 3000 s/h |

| Height of cutting rules | 23.8mm |

| Pressure adjusting range | ±1mm |

| Minimum gripper margin | 10mm |

| Inner chase size | 1480*1080mm |

| Total power | 20.77KW |

| Machine's dimension(mm) | 4424*3472*1955 |

| Weight | 15 Tons |