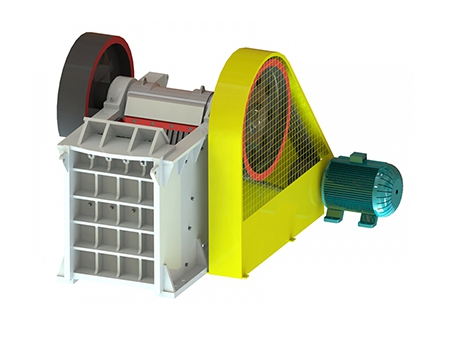

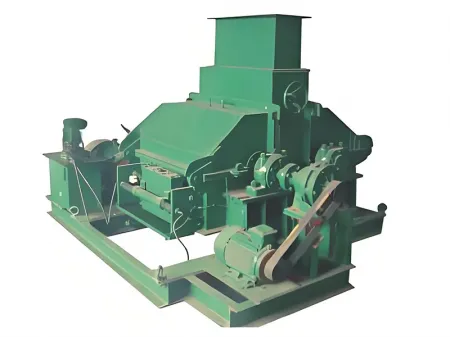

Toothed roll crusher

Double roll crusher features small volume, large reduction ration, low noise, simple structure, easy maintenance, high capacity, uniform finished product sizes, low over-crushing rate, sensitive overload protection, safety and reliability. It offers 5 to 8 reduction ratio and capacity which is 1 to 2 times higher than that of 2PCM teeth-roller crushed.

Compared with similar products in China, our double roll crusher has distinct advantages. The crusher integrates screening and crushing together. Two roller feature fixed installation. They rotates relatively to form a rotary grizzly. Particles with targeted sizes will leave from the clearance between two rollers or the clearance between rollers and the corresponding lining plates, thereby finishing preliminary screening and preventing these qualified particles from returning to the crusher for further grinding. As a result, over crushing rate and energy consumption are reduced significantly. The crushing time of each roller is decreased as well, which contributes to longer service time of the rollers. Two rollers adopted are designed with different sizes and don’t mesh with each other. They revolve oppositely at different speeds. As a result, improve shearing efficiency and tensile fragmentation effect will be enhanced greatly. Motion of the rollers will also forcefully push smashed materials out, thus avoiding clogging and making the crusher suitable for treatment of sticky or high water content materials.

The crusher is suitable for many areas such as coal industry, metallurgical industry, mineral industry, chemical industry and construction material industry. It is more applicable for raw ore grinding in large-scale mines or dressing plants. Based on the characteristics of different materials processed, the crusher will be matched with thick rollers or medium rollers.

Technical Parameters| Model | Roller Diameter (mm) | Roller Length (mm) | Maximum Feed Size(mm) | Discharge Size (mm) | Capacity (t/h) | Power Motor (kw) | Weight (kg) | Dimension (L×W×H) |

| 450 | 500 | 200-500 | 15-100 | 30-60 | 5.5×2 | 3800 | 2260×2200×766 | |

| 600 | 750 | 300-600 | 20-120 | 60-100 | 11×2 | 7200 | 2780×3065×1310 | |

| 600 | 900 | 300-600 | 30-150 | 80-120 | 18.5×2 | 7800 | 4500×1900×1350 | |

| 800 | 1050 | 500-800 | 30-150 | 100-160 | 22×2 | 12600 | 2550×2050×1100 | |

| 900 | 900 | 600-900 | 30-200 | 150-200 | 22×2 | 13500 | 2780×4100×1550 | |

| 1015 | 760 | 700-950 | 30-200 | 150-200 | 45×2 | 18800 | 7800×3200×1980 | |

| 1200 | 1500 | 800-1050 | 30-200 | 200-300 | 55×2 | 52000 | 8010×4500×2050 |