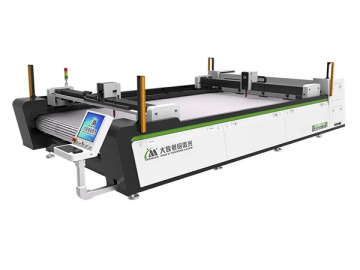

Textile Fabric Laser Cutting Machine,CMA1825C-DF-B/CMA2130C-DF-A

Applicable materials

Clothing, leather, sofa fabric, air bag, carpet, curtain and other textile fabrics

Technical Parameter

| Model | CMA1825C-DF-B | CMA2130C-DF-A |

| Working area (mm) | 2500×1800 | 3000×2100 |

| Laser tube | CO2 glass laser tube: 130W/280W; Domestic RF tube: 250W/450W; Imported RF tube: 130W/250W/350W/550W | |

| Motion system | Double laser head asynchronous/single laser head | |

| Maximum speed | 60m/min | |

| Power supply | 380V/50Hz | |

| Weight (kg) | 3000 | 4500 |

| Overall dimension (mm) | 5590×2980 ×1180 | 6050×3050×1260 |

| Working environment | Temp: 0~ 40°C Humidity: 0-80% No condensate | |

Samples:

Feature

1.Strengthened welded lathe bed and an imported finish milling processed gantry. The non-metal laser cutting machine is annealed and processed by vibration aging technology to relieve stress and control the deformation deviation within ±0.02mm.

2.Double guide rail asynchronous laser cutting system is capable of reasonably distributing two cutting heads to process diverse-sized and irregular-layout images in a same cutting area to improve working efficiency and save materials.

3.Rack double servo drive system enables a maximum processing speed of 60m/min.

4.The self-developed crossbeam is processed by finite element method and dynamic simulation analysis technology, whose material is aviation grade high-strength cast aluminum alloy, featuring light weight, good rigidity and excellent dynamic performance.

5.Fully automatic refuel lubrication system, maintenance-free, time-saving, ensuring the 24-hour continuous running.

6.Applicable for various soft fabrics.