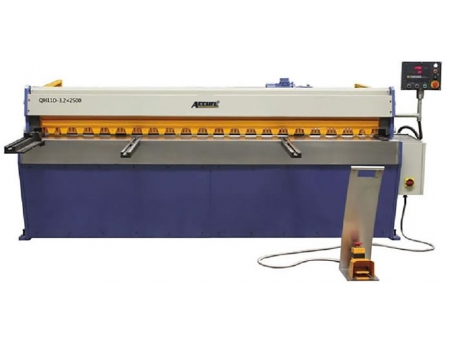

Hydraulic Guillotine Shear

Main Features

1. Totally EU streamlined design, monoblock by welding robots & aparatus and stress relief process by Annealing treatment.

2. The cutting beam of hydraulic guillotine shear has been designed in inner-inclined structure with adjustable cutting angle and blade gap.

3. The upper beam is able to move on the linear guide under the push of cylinder, to realize the shearing action.

4. Standard subsection blade with 4 cutting edges, quality high-carbon high-chrome blades D2 quality.

5. This guillotine shearing machine adopt integrated hydraulic system, more reliable and easy for maintenance. and the hydraulic system from Bosch-Rexroth, Germany,

6. This sheet metal cutting equipment adopts three point supporting type rolling guideway to raise shearing precision.

7. CE conformity including tiltable fornt finger guard and optical rear safety guard,

8. High quality shear blades, service kit, colours are light/dark grey and yellow.

Standard Equipment

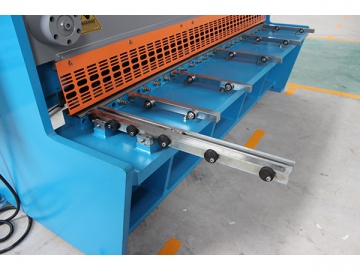

1. Rapid and precise blade clearance adjustment by handwheel on the side frame

2. Multi edge blades for cutting aluminium, mild steel and stainless steel

3. Cutting line illumination and wire for shadow line cutting

4. Counter of strokes, cutting length adjustment

5. The sheet metal shear uses hydraulic and electrical overload protection

6. Squaring arm and front support arms

7. Bed infill plates with ball transfers

8. Adjustable sound angle & blade gap

9. The hydraulic guillotine shear adopt Delta inverter with ball screw and polished rod with 0,01 mm accuracy.

Estun E21s NC Control system

1. Monochrome LCD box panel.

2. Integral factor programmable freely

3. Automatic positioning control

4. Spindle allowance offset

5. Internal time relay

6. Stock counter

7. Backgauge position display, resolution in 0.01mm

| Model (AC/MS8) | ||||||

| Cut Thickness | mm | 6 | 8 | 10 | 12 | 12 |

| Cut Thickness | mm | 3200 | 3200 | 3200 | 3200 | 4000 |

| Shear Angle | Degree | 0.5 ° -2.5 ° | 0.5 ° -2.5 ° | 0.5 ° -2.5 ° | 0.5 ° -2.5 ° | 0.5 ° -25° |

| SPM | min-1 | ≥ 15 | ≥ 15 | ≥ 15 | ≥ 6 | ≥ 6 |

| Back Gauge | mm | 20-600 | 20-600 | 20-600 | 20-800 | 20-1000 |

| Throat Depth | mm | 100 | 100 | 100 | 100 | 100 |

| Main Motor | kW | 7.5 | 11 | 11 | 18.5 | 30 |

| Net Weight | kg | 6200 | 8000 | 8000 | 12000 | 21000 |

| Outline Size | mm | 3740×1680×1750 | 3740×1750×1750 | 3850×1750×1850 | 3850×1950×2300 | 4200×2380×2970 |

| Model(AC/MS8) | ||||||

| Cut Thickness | mm | 12 | 16 | 16 | 16 | 12 |

| Cut Thickness | mm | 6000 | 3200 | 4000 | 6000 | 4000 |

| Shear Angle | Degree | 0.5 ° -2.5 ° | 0.5 ° -2.5 ° | 0.5 ° -2.5 ° | 0.5 ° -2.5 ° | 0.5 ° -2.5° |

| SPM | min-1 | ≥ 8 | ≥ 12 | ≥ 10 | ≥ 6 | ≥ 5 |

| Back Gauge | mm | 20-1000 | 20-1000 | 20-1000 | 20-1000 | 20-1000 |

| Throat Depth | mm | 100 | 100 | 100 | 100 | 100 |

| Main Motor | kW | 18.5 | 18.5 | 18.5 | 22 | 30 |

| Net Weight | kg | 29500 | 13500 | 16300 | 36500 | 75500 |

| Outline Size | mm | 6940×2480×2750 | 3850×2150×2050 | 4650×2150×2250 | 6950×2550×2650 | 9000×3280×3270 |