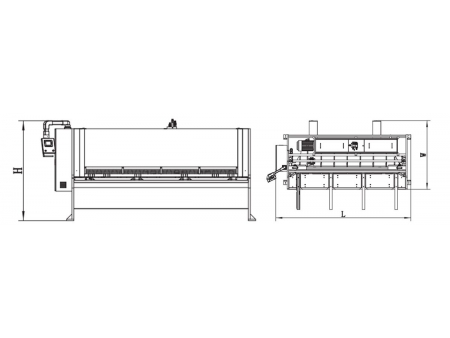

CNC Hydraulic Guillotine Shear

VAC Series

VAC Series

CNC hydraulic guillotine shear incorporates cutting-edge technology from the industry, ensuring high efficiency and reliability. Additionally, it provides the flexibility to be equipped with a wide range of intelligent auxiliary devices, further enhancing its capabilities.

(cutting thickness: 6 to 16mm)

| Model | Max. shearing thickness (mm) | Max. shearing length (mm) | Distance between uprights | Strokes (n/min) | Backgauge stroke (mm) | Shearing angle (°) | Main power (kW) | Oil volume (L) | Dimensions (L*W*H)(mm) | Weight (kg) |

| 6 | 4050 | 4420 | 15 | 600 | 1.5 | 11 | 300 | 4800*1720*1950 | 9600 | |

| 6 | 3050 | 3600 | 16-40 | 1000 | 0.5-2.5 | 15 | 300 | 4030*2116*2100 | 8400 | |

| 6 | 4050 | 4620 | 14-33 | 1000 | 0.5-2.5 | 15 | 300 | 5060*2200*2270 | 11500 | |

| 6 | 5050 | 5620 | 10-25 | 1000 | 0.5-2 | 15 | 360 | 6100*2200*2300 | 16000 | |

| 6 | 6050 | 6620 | 7-20 | 1000 | 0.5-2 | 15 | 360 | 7100*2300*2500 | 20000 | |

| 8 | 3050 | 3600 | 12-30 | 1000 | 0.5-2.5 | 15 | 300 | 4030*2116*2100 | 9500 | |

| 8 | 4050 | 4620 | 9-22 | 1000 | 0.5-2.5 | 15 | 300 | 5060*2300*2365 | 12500 | |

| 8 | 5050 | 5620 | 7-16 | 1000 | 0.5-2 | 22 | 360 | 6100*2200*2300 | 20000 | |

| 8 | 6050 | 6620 | 6-16 | 1000 | 0.5-2 | 22 | 360 | 7100*2300*2500 | 28000 | |

| 10 | 3050 | 3620 | 12-30 | 1000 | 0.5-2.5 | 22 | 420 | 4080*2165*2260 | 12000 | |

| 10 | 4050 | 4620 | 10-24 | 1000 | 0.5-2.5 | 22 | 420 | 5205*2320*2300 | 15000 | |

| 10 | 6050 | 6640 | 6-18 | 1000 | 0.5-2 | 22 | 420 | 7250*2350*2800 | 36500 | |

| 13 | 3050 | 3620 | 12-26 | 1000 | 0.5-2.5 | 30 | 540 | 4250*2300*2415 | 13700 | |

| 13 | 4050 | 4620 | 10-22 | 1000 | 0.5-2.5 | 30 | 540 | 5205*2350*2485 | 17000 | |

| 16 | 3050 | 3640 | 8-18 | 1000 | 0.5-2.5 | 30 | 540 | 4235*2300*2485 | 16000 | |

| 16 | 4050 | 4640 | 7-15 | 1000 | 0.5-2.5 | 30 | 540 | 5235*2350*2585 | 21000 |

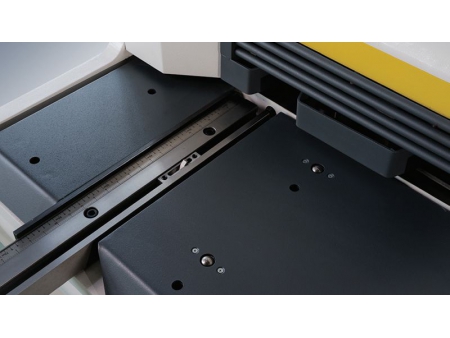

- Verticality adjustment and front positioning device

A solid squaring arm with a ruler is installed on the left side of the machine. It ensures precise cutting by providing front positioning and aiding in vertical adjustment.

- CNC shear blade gap adjustment mechanism

The system automatically adjusts the gap between the upper and lower blades to improve the cutting quality.

- High precision backgauge system

Backgauge device automatic backgauge lifting structure

The combination of precision ball screw, linear guide structure and high performance servo motor drive ensures the positioning accuracy. - Light-to-wire and pressurized material device

- Hydraulic system

The integrated hydraulic system effectively reduces hydraulic oil leakage.

- Steel ball transfer structure of working table

The rolling steel balls reduces frictional resistance and ensures that the surface of the workpiece is not scratched during processing.

- CNC system

Switzerland Cybelec CT8

- Pneumatic rear sheet support device

- Movable front pallet

- Angle positioning device

- CNC clearance adjustment device

- CNC front feeding device

- Rear pallet discharging device