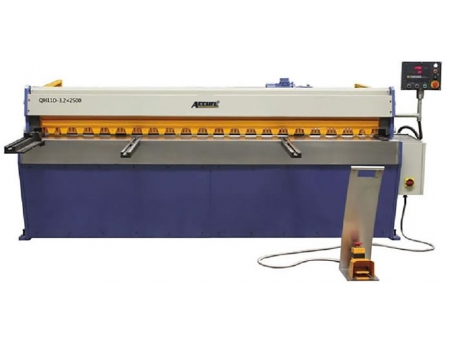

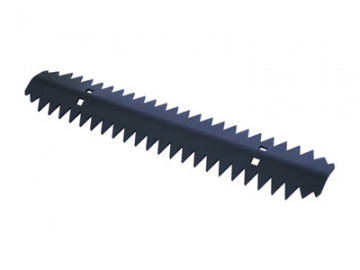

CNC Hydraulic Guillotine with Variable Rake

DC/MS8 Series

ACCURL, known as one of the top worldwide manufacturers in the sheet metal industry, proudly announces its latest shear model to the market, Variable Rake Hydraulic Guillotine Shear CNC DC/MS8.

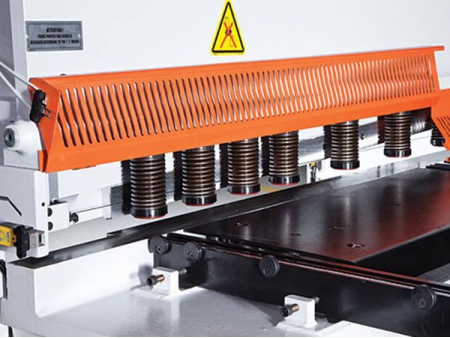

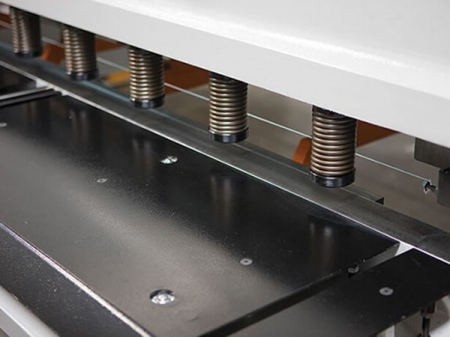

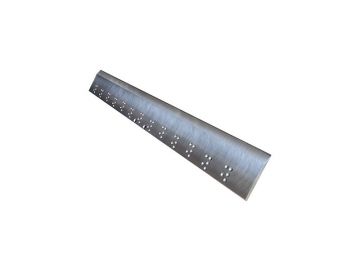

Blade gap, cutting angle and cutting length are all adjusted based on material selection and thickness automatically.

By choosing the new and improved CNC hydraulic guillotine DC/MS8, you will bring modern-day technology to your company with maximum safety, high accuracy and unique ease of use.

This sheet metal machinery can cut all kind of metal sheet to maintain the highest production capacity with maximum precision and guality.

ACCURL metal shearing machine improves its reliability every day by working with highly educated engineers and by using the latest technology in rapidly developing sheet metal industry. By using world standard steel, hydraulic systems and electronic products all your production needs provided.

CNC hydraulic variable rake guillotine DC/MS8 is developed by expert engineers of ACCURL reflects innovative technology with all aspects of it.

User - friendly

- Wide, bright, colorful to program easily.

- The hydraulic rake shear is easy to control.

- Complete part programming in seconds.

- Quick machine set up with EasyCut page.

- Contextual help and warning pop-up.

Improved Features

- Auto shutdown function for energy saving.

- 10 different language selection.

- Our sheet metal shear can save you working time.

- Wireless communication via PC/Laptop (optional).

- Backgauge auto-retraction programming.

Better Cuttings

- Backgauge adjustment according to blade gap.

- Backgauge retraction feature.

- Sub-program and programming loop.

- Sequence repeat function.

- Automatic calculations of cutting functions upon material specifications.

- More cutting sequence and programming memory.

The best cutting results You can cutt longer and narrow parts with standard DC/MS8-Cutt Series.

| Model(DC/MS8) | DC/MS8 | ||||||||

6×3050 | 6×4050 | 8×3050 | 8×4050 | 10×3050 | 10×4050 | 13×3050 | |||

| Cut Thickness | Stainless Steel | mm | 6.5 | 6.5 | 8 | 8 | 10 | 16 | 16 |

| Normal Steel | mm | 4 | 4 | 6.5 | 6.5 | 8 | 8 | 10 | |

| Cutting Length | mm | 3050 | 4050 | 3050 | 4050 | 3050 | 4050 | 3050 | |

| Cutting Angle | ° | 0.5-2.0 | 0.5-2.0 | 0.5-2.0 | 0.5-2.0 | 0.5-2.0 | 0.5-2.5 | 0.5-2.5 | |

| Back Gauge Stroke | mm | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | 1000 | |

| Back Gauge Speed | mm/s | 220 | 220 | 200 | 200 | 200 | 200 | 200 | |

| Back Gauge Accuracy | mm | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | ±0.01 | |

| Oil Tank | L | 200 | 200 | 200 | 200 | 250 | 300 | 300 | |

| Weight | kg | 7500 | 10000 | 10000 | 12000 | 32000 | 36000 | 85000 | |

| Outline Size (L×W×H) | mm | 3888×2580 ×2580 | 5000×2700 ×1930 | 4000×2750 ×1876 | 5120×2890 ×1986 | 7020×2550 ×2870 | 7020×2550 ×2870 | 9200×3250 ×3520 | |