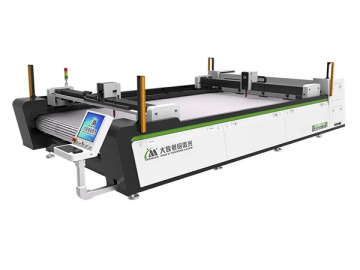

Textile Laser Cutting Machine

TextileLaser Cutting Machine

YH-G

Technical Parameters

| 60W、80W、100W CO2 glass laser tube | |

| Cutting size | 1400× |

| Cutting speed | ≤ |

| Engraving speed | ≤ |

| Repositioning accuracy | ± |

| Control system | 3 phase asynchronous motor, Built-in off-line control system |

| Power supply | AC220V,50HZ |

| Graphic file format | AI、BMP、PLT、DXF 、DST |

| Dimensions | 1890×1550× |

| Working temperature | 5 |

| Working environment humidity | 5-95﹪ |

High precision lead screw transmission system is adopted to achieve high speedengraving and cutting, and has advantages of high cutting precision, smooth cutedge and low cost. Bar-type worktable with wheels can make moving heavy

Besides, laser tube is the most important part of the laser cutting machine. Inorder to extend the laser tube service life, water pump and water coolingsystem are installed to cool the glass tube and protect laser tube from overhigh temperature. Also a siren system is adopted to protect the laser tube. Inaddition, it is to be noted that our textile laser cutting equipment can befully made use of, when it works under 5to