Torsion Bar Press Brake, TP10S

The torsion bar press brake is an essential machine in the sheet metal industry, designed for precise bending and forming of metal workpieces. It enables steel plates to be pressed into various shapes according to specific production requirements, ensuring accuracy and efficiency in metal fabrication.

- Material Carbon steel, alloy steel, aluminum alloy, copper alloy, high-speed steel, carbide alloy

- Length 10-6000

- Width 10-1500

- Thickness 0.5-20

- Angle 0-180 degrees

- Accuracy 0.1-0.3mm

- Shapes V Shape, U Shape, Z Shape, L Shape

| Model | Nominal Pressure (kN) | Workbench Length (mm) | Throat Depth (mm) (D) | Column Spacing (mm)(A) | Slide Stroke (mm) (B) | Max. Opening Height (mm)© | Main Motor Power (kW) |

| 630 | 2500 | 280 | 2050 | 120 | 350 | 5.5 | |

| 800 | 2500 | 320 | 2050 | 120 | 370 | 7.5 | |

| 1000 | 2500 | 400 | 2050 | 120 | 370 | 7.5 | |

| 1250 | 2500 | 400 | 2050 | 140 | 40 | 7.5 | |

| 1000 | 3200 | 400 | 2560 | 120 | 370 | 7.5 | |

| 1250 | 3200 | 400 | 2560 | 140 | 370 | 7.5 | |

| 1600 | 3200 | 400 | 2550 | 180 | 460 | 11 | |

| 2000 | 3200 | 400 | 2500 | 200 | 470 | 11 | |

| 2500 | 3200 | 400 | 2500 | 250 | 550 | 18.5 | |

| 3000 | 3200 | 400 | 2500 | 250 | 560 | 22 | |

| 1000 | 4000 | 400 | 3160 | 120 | 370 | 7.5 | |

| 1250 | 4000 | 400 | 3150 | 140 | 370 | 7.5 | |

| 1600 | 4000 | 400 | 3150 | 180 | 460 | 11 | |

| 2000 | 4000 | 400 | 3100 | 200 | 470 | 11 | |

| 2500 | 4000 | 400 | 3100 | 250 | 550 | 18.5 | |

| 3000 | 4000 | 400 | 3100 | 250 | 560 | 22 | |

| 4000 | 4000 | 400 | 3100 | 300 | 600 | 30 |

-

Utilizes advanced CNC technology to achieve high-precision bending, accommodating complex shapes and angles with minimal manual intervention. The high level of automation significantly boosts production efficiency, reducing labor involvement and downtime.

-

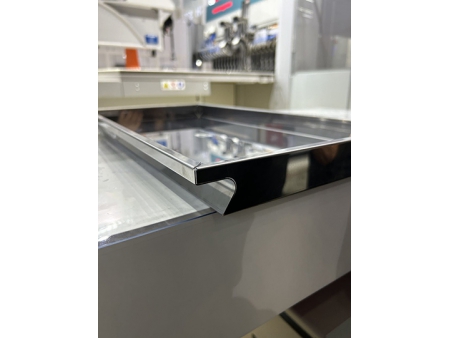

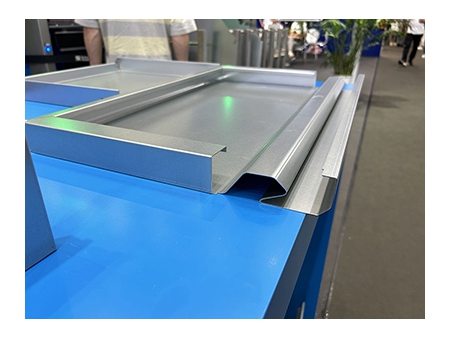

Built with a fully welded machine frame and assembled worktable, ensuring exceptional stability and durability for long-term operation.

-

The CNC system allows precise control over bending angles, bending length, and ram stroke, enabling efficient and highly accurate bending operations.

- Plunger Pump

- Hydraulic System

- Servo Motor

- Backgauge Ball Screw, Linear Guide Rail

- Backgauge Finger

- Electrical Cabinet

- TP10S

- E300

- DA-41S