Hybrid Press Brake, DNP Series

Request a Quote

Features

- Equipped with the HAWE ePrAX® hybrid pump control system, this hybrid bending machine enhances performance by 30% through reduced cycle time (shorter ramp-up time), saves 70% energy, 80% hydraulic oil, and reduces noise by 15%.

- No hydraulic piping connections are required, significantly lowering the hydraulic system failure rate.

- Achieves 5μm positioning accuracy.

- Offers a standard maintenance cycle of 7,000 working hours.

- Features full worktable compensation, with compensation wedges that better match the actual deformation curve of the machine, ensuring improved overall angle and straightness of the workpiece.

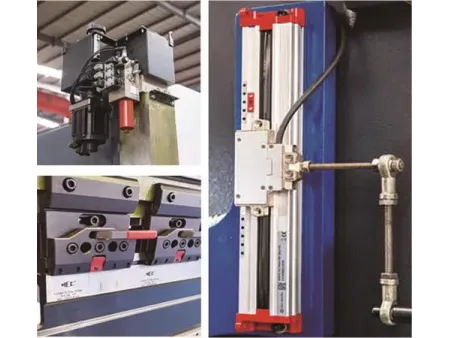

- Convenient tooling loading and unloading: tooling can be side-loaded or vertically installed and removed by pressing the red point, with the added functionality of tooling locking.

- Provides real-time feedback on slider position, ensuring precise bending angles.

Parameters

| Model | | | |

| Energy saving | 60-70% | 30-40% | 0 |

| Hydraulic oil saving | 70-85% | 0 | 0 |

| Speed increasing | 130% | 100% | 100% |

| Main motor | Servo motor * 2 | Servo motor * 1 | Electric motor * 1 |

| Oil pipe connection | No need | Need | Need |

| Aging time of hydraulic parts | Very slow | Slow | Normal |

| Noise level | Very low | Low | Normal |