CNC Torsion Bar Press Brake

Sheet metal bending machine with servo motor for high repeatability bending

Sheet metal bending machine with servo motor for high repeatability bending

Key Specs

- Norminal force: 630-3000KN

- Ram stroke: 100-250mm

- Throat depth: 250-400mm

- Open height: 320-590mm

- Features

- Specifications

- Examples

- Components

This CNC torsion bar press brake is equipped with a servo-driven torsion bar, reducer, encoder, controller, and a hydraulic system, making it an essential tool for the stainless steel metal processing industry. Featuring a CNC control system, it allows for programmable angles, simplifying and enhancing the bending process.

The press brake is primarily used for bending stainless steel metal in various forms, including stainless steel pools, elevator doors, electrical cabinet shells, precision sheet metal parts.

- Offers deepened throat depth and enhanced daylight opening for specialized tasks.

- DA41T (Delem) provides straightforward and easy programming capabilities.

- Mechanical adjustment ensures accurate bending angles.

- Incorporates a Schneider Electric panel to ensure reliable operation.

| Model | Nominal force (KN) | Working table length (mm) | Distance between uprights (mm) | Ram stroke (mm) | Throat depth (mm) | Max. open height (mm) | Power (kW) |

| 630 | 2500 | 1900 | 100 | 250 | 320 | 5.5 | |

| 630 | 3200 | 2600 | 100 | 250 | 320 | 5.5 | |

| 800 | 2500 | 1900 | 120 | 300 | 320 | 7.5 | |

| 800 | 3200 | 2600 | 120 | 320 | 350 | 7.5 | |

| 1000 | 2500 | 1900 | 150 | 320 | 350 | 7.5 | |

| 1000 | 3200 | 2600 | 150 | 320 | 370 | 7.5 | |

| 1000 | 4000 | 3200 | 150 | 320 | 370 | 7.5 | |

| 1250 | 3200 | 2600 | 150 | 320 | 370 | 7.5 | |

| 1250 | 4000 | 3200 | 150 | 320 | 370 | 7.5 | |

| 1600 | 3200 | 2600 | 200 | 320 | 460 | 11 | |

| 1600 | 4000 | 3200 | 200 | 320 | 460 | 11 | |

| 1600 | 5000 | 4000 | 200 | 320 | 460 | 11 | |

| 1600 | 6000 | 5000 | 200 | 320 | 460 | 11 | |

| 2000 | 3200 | 2600 | 200 | 320 | 460 | 11 | |

| 2000 | 4000 | 3200 | 200 | 320 | 460 | 11 | |

| 2000 | 5000 | 4000 | 200 | 320 | 460 | 11 | |

| 2000 | 6000 | 5000 | 200 | 320 | 460 | 11 | |

| 2500 | 3200 | 2600 | 250 | 400 | 590 | 18.5 | |

| 2500 | 4000 | 3200 | 250 | 400 | 590 | 18.5 | |

| 2500 | 5000 | 4000 | 250 | 400 | 590 | 18.5 | |

| 2500 | 6000 | 5000 | 250 | 400 | 590 | 18.5 | |

| 3000 | 3200 | 2600 | 250 | 400 | 590 | 22 | |

| 3000 | 4000 | 3000 | 250 | 400 | 590 | 22 | |

| 3000 | 5000 | 4000 | 250 | 400 | 590 | 22 | |

| 3000 | 6000 | 5000 | 250 | 400 | 590 | 22 |

- Stainless steel decoration industry

- Stainless steel household equipment

- Stainless steel tray

- Precision sheet metal

- Stainless steel electrical cabinet

- Channel steel

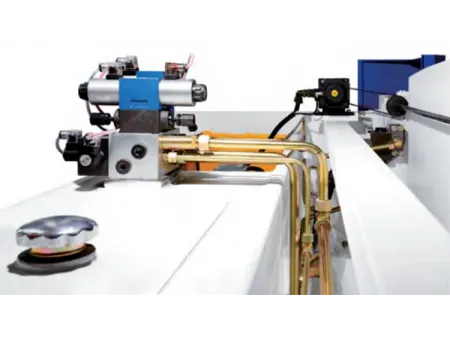

Servo-driven Y-axis for precise positioning

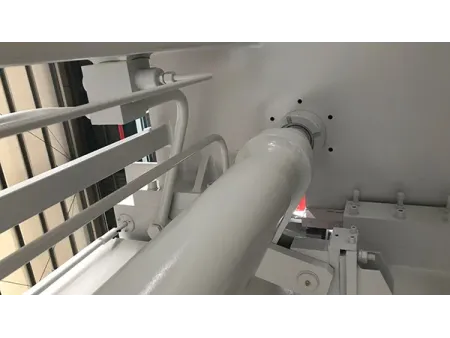

Torque bar for synchronous control

Integrated hydraulics to minimize piping, enhancing maintenance efficiency

Features quick die set clamping for fast and easy die changes

Standard top and bottom dies

Manual crowning system for accurate bending