Closed Circuit Fluid Bed Dryer

Application

1. The closed circuit fluid bed dryer is mainly used for solvent recovery and drying of solvent based materials.

2. For drying of materials with solvent from sway granulators and high-speed mixing granulator.

3. For drying of wet granules and powder granules with solvent in the food, chemical, and pharmaceutical industry.

4. For drying of large granules, small blocks and low-viscosity material.

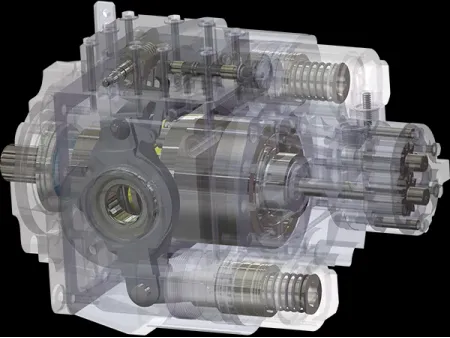

Working principle

Features and advantages

1. High efficiency

The fluid bed dryer features a fully enclosed structure with no dead corners, both an air exhaust system and an air intake system that can handle high temperatures. The entire drying unit features 3 levels of dust catcher. After drying is finished, the blowback system eliminates residual dust that reduces cleaning frequency.

The drying machine can work continuously and steadily for long term operation with a high degree of automation. It can dry, cool solvents and cool raw materials with a drying efficiency 4 to 5 times higher compared to similar machines.

According to the user requirements, a vacuum feeder and vacuum discharger are optional.

2. Safety

Due to the flammable and combustible nature of some organic solvents, this machine is carefully designed with safety technologies, including oxygen sensors, gas ventilation and so on. Through special control technology, the oxygen level and pressure balance can be accurately monitored at all times. If the levels rise too high, the machine has systems in place to supply nitrogen in order to prevent combustion as well as a ventilation action to relieve pressure or remove dangerous gas. The system is designed to automatically kick in in order to prevent explosion.

3. Energy Savings

This drying equipment is a fully enclosed system that makes efficient use of heat with minimal dissipation. The pressure within the drying chamber is kept low in order to maximize drying efficiency as well.

After drying, the hot air that has been mixed with solvents is separated by a condensator. The recovered solvent can then be reused. Also, the machine uses low dew point nitrogen for cyclic utilization. Compared with common dryers, the thermal efficiency and lower power consumption of this machine make it the smart choice when purchasing drying machines.

4. Environmental protection

The dryer's ability to recover the solvent from raw materials during drying helps prevent the release of pollutants.

Technical Parameters

| Model | 60 | ||

| Item | Unit | ||

| Container of raw material | Dia. | Mm | Φ900 |

| Production capacity | Min | kg/batch | 40 |

| Max | kg/batch | 65 | |

| steam consumption | kg/batch | 130 | |

| Nitrogen consumption | m3 /min | 0.6 | |

| Power of fan | kw | 11 | |

| Solvent recovery percentage | % | ≥95 | |

| Temperature | ℃ | room temperature to 140℃,Adjustable according to material features | |

| Product ratio | % | >99 | |

| Final moisture | % | ~0.2 | |

| Noise | db(A) | ≤75 | |

| Overall dimensions(LxW) | mm | 6852X3740 | |

| Height | H1 | mm | 4800 |

| H2 | mm | 4000 | |

| Model | 120 | ||

| Item | Unit | ||

| Container of raw material | Dia. | Mm | Φ1000 |

| Production capacity | Min | kg/batch | 70 |

| Max | kg/batch | 135 | |

| steam consumption | kg/batch | 210 | |

| Nitrogen consumption | m3 /min | 0.6 | |

| Power of fan | kw | 18.5 | |

| Solvent recovery percentage | % | ≥95 | |

| Temperature | ℃ | room temperature to 140℃,Adjustable according to material features | |

| Product ratio | % | >99 | |

| Final moisture | % | ~0.2 | |

| Noise | db(A) | ≤75 | |

| Overall dimensions(LxW) | mm | 7266X3803 | |

| Height | H1 | mm | 5500 |

| H2 | mm | 4100 | |

| Model | 150 | ||

| Item | Unit | ||

| Container of raw material | Dia. | Mm | Φ1100 |

| Production capacity | Min | kg/batch | 90 |

| Max | kg/batch | 170 | |

| steam consumption | kg/batch | 240 | |

| Nitrogen consumption | m3 /min | 0.9 | |

| Power of fan | kw | 22 | |

| Solvent recovery percentage | % | ≥95 | |

| Temperature | ℃ | room temperature to 140℃,Adjustable according to material features | |

| Product ratio | % | >99 | |

| Final moisture | % | ~0.2 | |

| Noise | db(A) | ≤75 | |

| Overall dimensions(LxW) | mm | 7340X3910 | |

| Height | H1 | mm | 5750 |

| H2 | mm | 4200 | |

| Model | 200 | ||

| Item | Unit | ||

| Container of raw material | Dia. | Mm | Φ1400 |

| Production capacity | Min | kg/batch | 120 |

| Max | kg/batch | 250 | |

| steam consumption | kg/batch | 280 | |

| Nitrogen consumption | m3 /min | 0.9 | |

| Power of fan | kw | 30 | |

| Solvent recovery percentage | % | ≥95 | |

| Temperature | ℃ | room temperature to 140℃,Adjustable according to material features | |

| Product ratio | % | >99 | |

| Final moisture | % | ~0.2 | |

| Noise | db(A) | ≤75 | |

| Overall dimensions(LxW) | mm | 7550X4330 | |

| Height | H1 | mm | 5750 |

| H2 | mm | 4420 | |

| Model | 300 | ||

| Item | Unit | ||

| Container of raw material | Dia. | Mm | Φ1600 |

| Production capacity | Min | kg/batch | 150 |

| Max | kg/batch | 355 | |

| steam consumption | kg/batch | 360 | |

| Nitrogen consumption | m3 /min | 1.1 | |

| Power of fan | kw | 37 | |

| Solvent recovery percentage | % | ≥95 | |

| Temperature | ℃ | room temperature to 140℃,Adjustable according to material features | |

| Product ratio | % | >99 | |

| Final moisture | % | ~0.2 | |

| Noise | db(A) | ≤75 | |

| Overall dimensions(LxW) | mm | 8420X4620 | |

| Height | H1 | mm | 6540 |

| H2 | mm | 4620 | |

| Model | 400 | ||

| Item | Unit | ||

| Container of raw material | Dia. | Mm | Φ1800 |

| Production capacity | Min | kg/batch | 255 |

| Max | kg/batch | 480 | |

| steam consumption | kg/batch | 500 | |

| Nitrogen consumption | m3 /min | 1.6 | |

| Power of fan | kw | 45 | |

| Solvent recovery percentage | % | ≥95 | |

| Temperature | ℃ | room temperature to 140℃,Adjustable according to material features | |

| Product ratio | % | >99 | |

| Final moisture | % | ~0.2 | |

| Noise | db(A) | ≤75 | |

| Overall dimensions(LxW) | mm | 9870X5520 | |

| Height | H1 | mm | 6540 |

| H2 | mm | 4700 | |

| Model | 500 | ||

| Item | Unit | ||

| Container of raw material | Dia. | Mm | Φ2000 |

| Production capacity | Min | kg/batch | 355 |

| Max | kg/batch | 580 | |

| steam consumption | kg/batch | 600 | |

| Nitrogen consumption | m3 /min | 2 | |

| Power of fan | kw | 55 | |

| Solvent recovery percentage | % | ≥95 | |

| Temperature | ℃ | room temperature to 140℃,Adjustable according to material features | |

| Product ratio | % | >99 | |

| Final moisture | % | ~0.2 | |

| Noise | db(A) | ≤75 | |

| Overall dimensions(LxW) | mm | 10600X5600 | |

| Height | H1 | mm | 6600 |

| H2 | mm | 5050 | |

Flow Chart Drawing