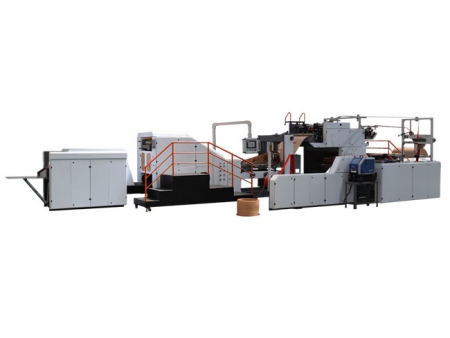

QT4-15 Automatic Block Making Machine

Model QT4-15 automatic block making machine provides an intelligent operating platform that helps machine operators stay in total control. The brick machine works relatively fast, delivering high productivity. If you are in need of a high-efficiency brick making machine, please feel free to contact one of our technicians or sales representatives with your specific requirements.

Features of QT4-15 Automated Block Making Machine

1. The electrical system utilizes imported color touch screen for easy operation. Advanced PLC system comes with I/O ports, and has security control and machine fault diagnosis functions.

2. Imported hydraulic parts and sealing components, coupled with advanced proportional valves, allow operators to precisely control the movements of key parts via adjusting hydraulic flow and pressure.

3. The main body of this block making machine is a precision machined casting. Unique welding technology allows the body to be mechanically strong, rigid, vibration resistant and durable.

4. Four guiding rods are used to guide the precise movement of the tamper head and mold.

5. Vibratory worktable keeps agitating the mix while the tamper head comes down to press and compact the material into shape. Oscillating screen feeds the material evenly into each mold. The resulting molded block is solid, strong, and has accurate sizes.

6. Model QT4-15 automated concrete block machine represents a unique combination of mechanical, electrical, and hydraulic technologies which enable it to deliver high repeatability from cycle to cycle. Combined technologies are also part of the reason why our brick maker could deliver a lower than average scrap rate.

7. Simply change the molds used on the automatic block making machine and users can produce a variety of blocks such as the perforated brick, hollow brick, curbstone, paver block, turf bock, retaining-wall block, and more.

Note that the machine can also be used to produce colored paver blocks with face mix.

| Brick Specifications | Samples | pcs/mold | pcs/h | pcs/8h | 1 year (300 days) |

| Blocks 390×190×190mm 71pcs/m3 | 4 | 720 | 5760 | 24338m3 | |

| Blocks 390×100×190mm 135pcs/m3 | 8 | 1440 | 11520 | 25600m3 | |

| Dutch Bricks 200×100×60mm 50pcs/m2 | 14 | 2520 | 20160 | 120960m2 | |

| Dog-Bone Bricks 200×165×60mm 30pcs/m2 | 8 | 1440 | 11520 | 114059m2 | |

| Zigzag Bricks 225×112.5×60mm 40pcs/m2 | 12 | 2160 | 17280 | 131241m2 | |

| Perforated Bricks 240x115x90 402pcs/m3 | 12 | 2160 | 17280 | 5.18 million pcs | |

| Solid Bricks 240x115x53 683pcs/m3 | 24 | 4320 | 34560 | 10.37 million pcs |

| Dimension | 4850×4650×2250(mm) |

| Pallet Size | 850×550×16(PVC plate) |

| Weight | 4000kg |

| Vibration Efficiency | 50-90Hz |

| Maximum Excitation Force | 50KN |

| Molding Cycle | 15-20S |

| Installed Capacity | 21KW |