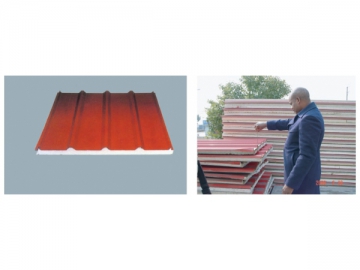

EPS and Rockwool Sandwich Panel Production Line

Request a Quote

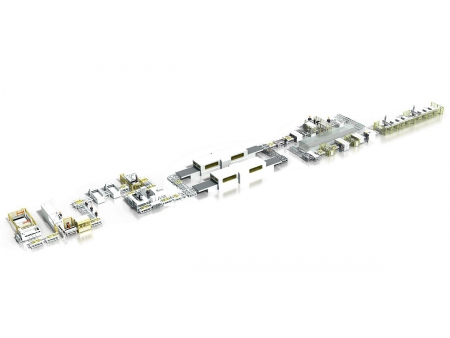

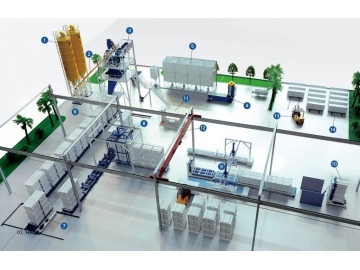

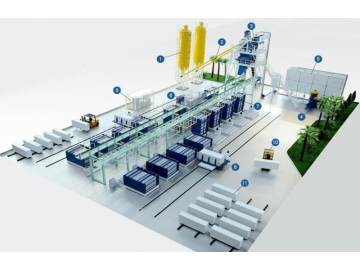

Using color-coated steel sheets as facings, the EPS and rockwool sandwich panel production line is built specially for a range of EPS and rockwool panels used as roofing and wall panels in cold storage warehouses, ordinary warehouses, factory buildings, temporary buildings, and pre-assembled buildings. The EPS and rockwool sandwich panel production line includes a double-layer roll forming machine for the production of both EPS panels and rockwool panels.

Technical Specs of 2-in-1 Sandwich Panel Production Line| Item | EPS and Rock wool |

| Material Thickness | 0.35~0.6mm |

| Color steel sheet width | 1000 mm 1200 mm 1250 mm (as per customer requirements) |

| Core material | EPS foam and rock wool material |

| Power supply | AC380/50-60Hz/3PH |

| Total power | 35KW |

| Production line speed | 0-6m/min |

| Single layer roll forming machine | -- |

| Double layer roll forming machine | 950 ridge cap for rock wool 980/960 lap joint for EPS |

| Equipment overall dimensions | 48000 x 3000 x 2800 (lengthening compound part is 8130mm) |

| Product thickness | EPS 50-250mm Rock wool 50~100mm |

| Annual output | 600 thousand square meters |

| Conveyor | Chain conveyor |

| Cutting system | With enclosed cabinet |

| Conveyor motor | Double motor |

| Pay-off stand | Passive damping force 5T |

| User interface | Canadian brand Xinje and PWS6600S-SA Taiwan brand QuanYi |

| PLC automatic controller | Canadian brand Xinje |

| VFD | Japanese brand YiNeng and VFD-M Taiwan brand DELTA |

| Encoder | OVW2-20MHC-2000 Japanese brands, measurement range (0-10m) |

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos