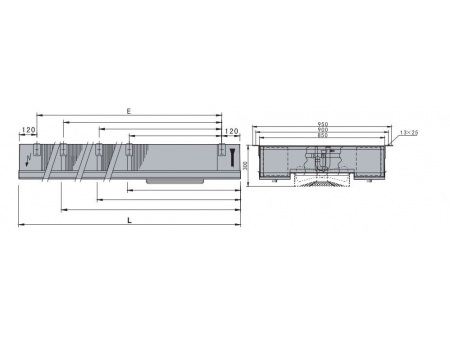

Pellet Cooler with Slide Valve Reciprocating Discharge Mechanism

Pellets cooling should be a gradual process done with a quality pellet cooler. If pellets are cooled too fast, cracks in the outer layer would be formed. If they are cooled too slowly, too much moisture is removed which would have financial consequences since water is the cheapest ingredient in the pellet feed.

Features of Pellet Cooler with Slide Valve Reciprocating Discharge System

1. The counter flow cooler works with an airflow that moves opposite to the pellet flow. Counter flow cooling prevents thermal shock and allows pellets to cool down in a gentle, even and gradual manner. Therefore, fracture or breakage in pellets is not a likely result from counter flow cooling. Available with an airlock feeder, the pellet cooler also provides a large opening to allow a large volume air to enter.

2. The so-called slide valve reciprocating discharge system is perhaps one of the technical bollocks that you wouldn't like to care about. But this slide gate is very useful in controlling the rate of discharge and ensuring minimum residue is left inside the outlet.

3. Easy to operate and repair, DEGAO pellet cooler helps you save energy while delivering optimized cooling processes.

4. Pellet temperature after cooling should be 3℃ to 5℃ higher than room temperature.

5. Suitable for cooling particulate matters.

| Model No. | |||||

| Cooling Capacity (m³) | 1.5 | 2.5 | 4.0 | 6.0 | 8.0 |

| Production Capacity (t/h) | 3 | 5 | 10 | 15 | 20 |

| Cooling Time (min) | No less than 10-15 | ||||

| Cooling Temperature ( ℃ ) | 3℃-5℃ higher than room temperature | ||||

| Air Intake (m³/min.t) | 34 | ||||

| Power (kw) | 0.75 | 1.10 | 1.50 | 1.50 | 1.50 |

| Airlock Feeder Power (kw) | 0.55 | 0.55 | 0.75 | 1.1 | 1.5 |