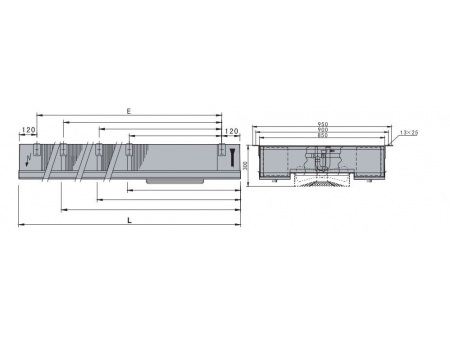

Pellet Cooler with Swing Discharge Mechanism

Hot pellets coming out from the pellet mill can not be stored immediately and need to be cooled first with an effective pellet cooler. Pellet cooling is a process that is more or less taken for granted, but is still an important part of feed processing.

Features of Pellet Cooler with Swing Discharge System

1. DEGAO pellet cooler works with an airflow that moves opposite to the pellet flow. During the time that air and product flow pass each other, they exchange energy and water. One advantage of counter flow cooling solution is that it allows hot pellets to cool down gradually rather than abruptly. Therefore, cracks in the pellet surface become less of an issue.

2. Available with an airlock feeder, the pellet cooler provides a large opening where high volumes of air can enter at once, which ensures excellent cooling performance.

3. Swing gate is installed to effectively discharge the cooled pellets with minimum residue.

4. Low energy consumption, great ease of use

5. A counter flow cooler mainly used for handling particulate matters and puffed grains.

| Model No. | |||||

| Cooling Capacity (m³) | 1.5 | 2.5 | 4 | 6 | 8 |

| Production Capacity (t/h) | 3 | 5 | 10 | 15 | 20 |

| Cooling Time (min) | No less than 10-15 | ||||

| Temperature after Cooling | 3℃ -5℃ higher than room temperature | ||||

| Air Intake (m³/min.t) | 34 | ||||

| Cooling Power (kw) | 0.75 | 1.1 | 1.5 | 1.5 | 1.5 |

| Power of Air Lock (kw) | 0.55 | 0.75 | 1.1 | 1.5 | 1.5 |