Hot Forming & Superplastic Forming Presses

Designed for the high-temperature forming of titanium, magnesium, aluminum, and other advanced alloys, these forming presses are essential for shaping high-strength components with complex geometries.

Hot forming and superplastic forming (SPF) technologies are widely used in aerospace, aviation, high-speed rail, and automotive industries to manufacture integrated structural parts and enable lightweight design of critical components. Our forming press solutions are engineered to meet the demanding requirements of these industries, particularly for materials that are difficult to form using conventional methods.

For components requiring deep cavities and high wall-thickness uniformity, we provide customized superplastic forming equipment paired with precision preforming dies. Through tailored process control and optimization of friction conditions across different areas, our forming press solutions ensure accurate, high-quality part formation.

- Reverse Bulge Exhaust Primary Bulge Inflation Vent Hole Reverse Bulge Inflation Pre-Forming Die Sheet Material Final Forming Die

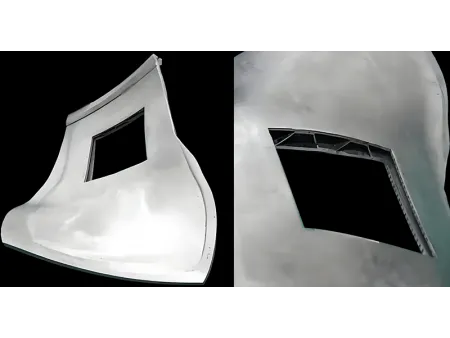

This complex, multi-layered titanium alloy component is manufactured using a combined process of stamping, superplastic forming, and diffusion bonding. Our advanced forming systems enable the one-step fabrication of aerodynamic hollow fan blades with superior strength and geometry widely used in aerospace engine applications.

| Model | Unit | ||||||||

| Nominal Force | kN | 1000 | 2000 | 3000 | 5000 | 10000 | 15000 | 20000 | |

| Ejecting force of drawing cylinder | kN | 100 | 100 | 150 | 200 | 630 | 1000 | 1500 | |

| Max. stroke of upper heating platen | mm | 600 | 800 | 800 | 1000 | 1200 | 1500 | 1200 | |

| Max. open daylight | mm | 800 | 1000 | 1000 | 1200 | 1400 | 1600 | 1600 | |

| Max. stroke of moving table | mm | ——— | 1800 | 1800 | 1800 | 2000 | 2500 | 2500 | |

| Effective area of heating platen | F-B | mm | 500 | 800 | 1200 | 1250 | 1800 | 1600 | 2000 |

| L-R | mm | 500 | 800 | 1200 | 1250 | 1400 | 1600 | 2000 | |

| Max. temperature of hot forming | ℃ | 950 | 950 | 950 | 950 | 950 | 950 | 950 | |

| Number of temperature controlled heating zones | Zones | 9 | 9 | 9 | 9 | 9 | 9 | 9 | |

| Surface temperature after cooling | ℃ | 40 | 40 | 40 | 40 | 40 | 40 | 40 | |

| Model | Unit | ||||||||

| Nominal Force | kN | 1000 | 2000 | 2500 | 3000 | 5000 | 8000 | 10000 | |

| Ejecting force of drawing cylinder | kN | 100 | 100 | 150 | 200 | 400 | 400 | 600 | |

| Max. stroke of upper heating platen | mm | 600 | 800 | 800 | 1000 | 1200 | 1200 | 1200 | |

| Max. open daylight | mm | 800 | 1000 | 1000 | 1200 | 1400 | 1400 | 1500 | |

| Max. stroke of moving table | mm | ——— | 1800 | 1800 | 1800 | 2000 | 2500 | 2500 | |

| Effective area of heating platen | F-B | mm | 500 | 800 | 1200 | 1250 | 1800 | 1600 | 3000 |

| L-R | mm | 500 | 800 | 1200 | 1250 | 1400 | 1600 | 1600 | |

| Max. temperature of hot forming | ℃ | 950 | 950 | 950 | 950 | 950 | 950 | 950 | |

| Max. temperature of superplastic forming | ℃ | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | 1100 | |

| Number of temperature controlled heating zones | Zones | 9 | 9 | 9 | 9 | 9 | 9 | 12 | |

Hot forming is a high-temperature, high-pressure metal forming process that utilizes the thermal plasticity of materials to shape complex components.

It is particularly suitable for titanium alloys, magnesium alloys, high-temperature alloys, and other high-strength metals that are difficult to form at room temperature.

During the hot forming process, both the die and the workpiece are heated, often up to 950°C, allowing the material to undergo controlled deformation with improved plasticity and elongation.

In some cases, semi-finished parts are re-formed under heat to enhance their mechanical properties and dimensional accuracy.

This process is essential for achieving lightweight, high-strength components in industries with demanding structural performance requirements.

Superplastic forming is a precision manufacturing process used to create complex, high-strength alloy components in a single step by exploiting the material’s superplastic behavior at elevated temperatures.

One commonly used method is TSPF (Two-Sheet Superplastic Forming), which combines extreme heat with inert gas like argon and may be integrated with diffusion bonding (SPF/DB) for advanced structural integrity.

In this process, the heated workpiece is clamped between a die cavity and a forming plate. Argon gas is then injected into the forming chamber, pressing the material into the cavity with uniform pressure. Typical forming temperatures range from 700°C to 1000°C, depending on the material.

Due to the precise thermal and mechanical demands of SPF, mold materials must exhibit high-temperature strength, excellent thermal stability, low thermal expansion, and cost-effective manufacturability.

This process is ideal for aerospace and high-performance applications where lightweight, intricately shaped parts are required without compromising material strength. gives operators exceptional control to form far more complex parts than possible with standard hot-forming processes.

Complete turnkey solutions for forming equipment and production lines