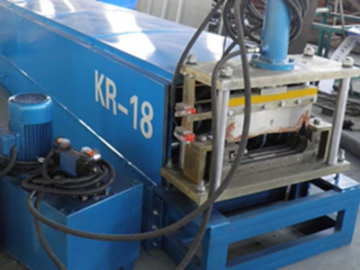

C10 Roll Forming Machine

The C10 roll forming machine is engineered to perform feeding, roll forming and cutting on sheet metal. It provides metal sheets with an aesthetically pleasing exterior, a uniform texture, high mechanical strength and a long-lasting performance.

This product can function as a wall panel forming machine or roofing sheet equipment for use in warehouses, workshops, garages, hangars, gyms, galleries, theatres, and other industrial and residential buildings. It consists of a roll forming unit, PLC-based computer control system, hydraulic power pack system, as well as a fully-automatic cutting system. It is noteworthy that our sheet metal machinery is designed with high-grade automatic control software for efficient production management. These roll forming products are specially built for use in Russia and the Philippines.

Parameters of the C10 Roll Forming Machine

| Total Length of Machine | 7.2m | Width | 1.6m | Height | 1.4m |

| Motor Power | 3kW 3kW | Operating Voltage | 380V | Production Speed | 10-15 m /min. |

| Shaft | 11-row shaft | Drive Method | 1.31inch chain drive | Roller | 45# steel, chrome plating |

| Machine Weight | Approx. 2.8T | Frame Material | 250H steel | Shaft Diameter | Ø80mm |

| Max. Error | The multi-row roll forming unit can deliver stable performance. Max. Length Error: ± 2mm | ||||

| Plate Width | Effective Width: 1000mm Feeding Width: 1250mm | ||||

| Shaft Diameter and Material | Shaft: ¢ 80 solid shaft Material: 45# tempered steel | ||||

| Machine Parts | Rolling forming unit, hydraulic system, computer control system and steel plate cutting unit | ||||

| Numerical Control System | The main control system includes ATMEL chips, a liquid crystal display, Omron or Panasonic relay, a low-voltage apparatus and a frequency converter. | ||||

| Counter | Optical rotary encoder, A40S6-600-2-12 -ACP | ||||

| Cutting Method | Hydraulic cutting, 3kW hydraulic power pack, 80×100 hydraulic cylinder, Cr12 quenched blade | ||||