Multi-Purpose Dual Table CNC router

Request a Quote

The NC-1318 multi-purpose dual table CNC router is equipped with two working tables, a lower one and a higher one; they are designed for engraving stone with 3D reliefs. The aluminum alloy working table with T-shaped grooves can use fixture to clamp various irregular shaped workpieces. It can do complex processing such as relief carving and hollow carving very conveniently.

This machine can process a wide scope of materials, such as granite, marble, artificial stone, ceramic, etc.

Technical parameters for available models

| Model | NC-1318 |

| Working Size | 1300*1800mm |

| Spindle Power | 5.5 kW |

| Control System | NC-STUDIO.DSP |

| Support Code | G Code |

| Software | Artcam |

| Motion Control | Stepper motors |

| Voltage | 380V, 50/60Hz |

| Spindle Speed | 0-24000rmp/min |

| Maximum Working Speed | 6000m/min |

| Positional Accuracy | ±0.03/300mm |

| Operating Temperature | 0℃ ~ 45℃ |

| Operating Humidity | 30% ~ 75% |

| Size | 3000*2250*2150mm |

| Weight | 1600kg |

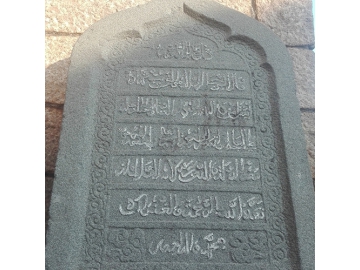

Samples

Features

- The body of multi-purpose dual table CNC router is welded by thick square pipes, which is lightweight and has good resistance to deformation.

- The body of the CNC router is full-length welded thick square pipe, and processed by technics of vibration stress. Though it is working in a high speed, the surface of processed workpieces will be smooth.

- The CNC router is equipped with a 5.5kw high-power, constant torque and high speed spindle, which ensures high processing efficiency, and the spindle is not easy to be damaged.

- X, Y and Z-axis bearings use linear guide rails to reach higher position accuracy.

- This CNC router machine uses racks in transmission system to ensure higher working speed.

- It has a stainless steel sink near the working table, which makes the cleanup of working table become more convenient after the cutting works.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos