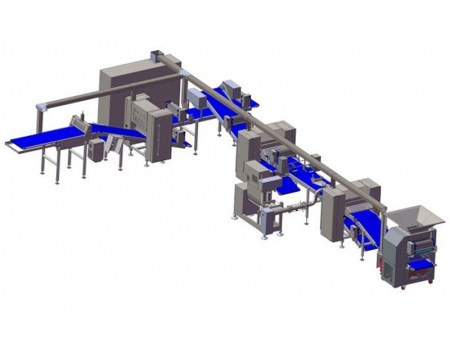

Compact Pastry Dough Laminating Line

The laminating line is used to produce typical laminated dough block. With less space needed and lower capital budget, this line is very popular to small and medium food factory. Repeat running of production processing, final laminated dough can be used to manufacture frozen puff, croissants, Danish pastry and other laminated products.

According to specific production processing requirements, the line number of laminators can be increased to form a continuous laminating line to produce the laminated dough sheet with ideal layers.

Equipped with freezer with adjustable temperature, the line can also make frozen pastry dough.

Dough hopper & extruder – Calibrator – Butter pump – Butter feeding & folding unit – Satellite – Laminator – Satellite – Guillotine – Panning machine

Note: Production processing, dough band width and thickness are able to be designed based on the real needs.

- Hopper & Extruder

- Calibrator

- Fat Pump

- Butter Feeding

- Satellite

- Lamination

- Flour Duster

- Guillotine

- Pastry Dough

| Industrial output | ≤1500kg/hr |

| Belt width | 650mm |

| Dough width | ≤600mm |

| Dough thickness | 3mm-30mm |

| Butter tier No. | ≤7 layers |

| Butter:dough | 1:1-1:10 |

| Power | 15kw |

| Line type | L shape |

| Line size | L 13.0m* W8.5m* H2.4m |

| Hopper height | 2100mm |

| Hopper volume | ≤ 200kg/time |

- Product quality is stable and pretty.

- The proportion of dough and butter can be adjusted according to specific demand;

- Equipped with Video monitoring equipment, easy to watch the running situation of main part to reduce the downtime.

- Abnormal data can be found and optimized by the remote control system.

- Thickness can be adjusted automatically. One-click switching of multiple products’ production can be achieved by saving formula.

- Hopper & extruder

To divide the mixed dough into pieces, and extrude the pieces into continuous dough band. Coming out dough band with 600mm; thickness 1.5~2.5 cm adjustable; With wheels, easy to remove when cleaning and maintenance - Calibrator

To reshape the dough band with ideal width and thickness and enable the dough with pretty texture. - Satellite/ Multi-roller

To further press the dough with needed width and thickness. With 12 smaller solid rollers above and 1 big roller underneath; Each smaller roller can be detached for cleaning. And the dough band thickness before and after satellite is Max. 10:1, and adjustable; - Fat pump

To squeeze the butter/ margarine / shortening out and folded into dough band with folding unit. - Laminator

To fold the dough band to get the layers. - Equipped with Freezer to produce frozen pastry dough

Max. capacity up to 2500kg/h of dough. Flexible modular design. Freezing temperature -40℃