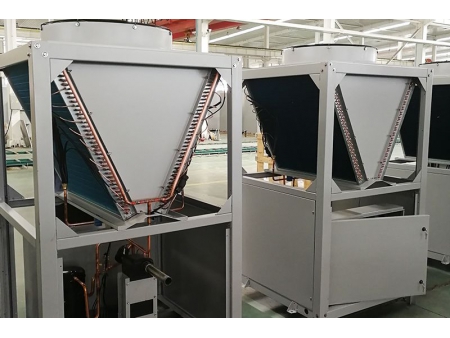

Mini Type Air Cooled Scroll Chiller and Heat Pump, 10kW-45kW

Request a Quote

Download

Technical Parameters

| Model | RLSFW20(R) | RLSFW25(R) | RLSFW30(R) | RLSFW40(R) | RLSFW45(R) | ||

| Nominal cooling capacity | kW | 21.5 | 23.1 | 27 | 32 | 43 | |

| Cooling input power | kW | 7.5 | 7.9 | 9 | 10.4 | 13.3 | |

| EER | 2.87 | 2.92 | 3.00 | 3.08 | 3.23 | ||

| Running current | A | 13.3 | 14 | 16 | 18.4 | 23.5 | |

| Nominal heating capacity | kW | 24.4 | 26.3 | 30 | 38.2 | 46.2 | |

| Heating input power | kW | 7.4 | 7.9 | 9 | 10.3 | 13.2 | |

| COP | 3.30 | 3.33 | 3.33 | 3.71 | 3.50 | ||

| Running current | A | 13.1 | 14.0 | 16.0 | 18.2 | 23.3 | |

| Max. running current | A | 20.6 | 21.5 | 24 | 27 | 35 | |

| Cable diameter (copper wire distance ≤20 meters) | mm² | 3*6 2*4 | 3*6 2*4 | 3*6 2*4 | 3*6 2*4 | 3*10 2*6 | |

| Power voltage | 380V/3PH/50HZ | ||||||

| Compressor | Type | Hermetic scroll type | |||||

| Quantity | 1 | 1 | 1 | 1 | 1 | ||

| Start mode | Direct start | ||||||

| Refrigerant | Type | R410A/R407C | |||||

| Charge (kg) | 4.5 | 5 | 6.5 | 8.5 | 10.5 | ||

| Control | Electronic expansion valve (EXV) | ||||||

| Evaporator | Type | Stainless steel plate type | |||||

| Water pressure drop | kPa | 70-90 | 70-90 | 70-90 | 70-90 | 70-90 | |

| Water pipe dia. DN | DN32 | DN32 | DN40 | DN40 | DN40 | ||

| Water flow | m³/h | 3.4 | 3.6 | 4.3 | 5.0 | 6.7 | |

| Condenser type | Internally threaded copper tube & hydrophilic aluminum fins | ||||||

| Condenser fan | Fan type | Axial | Axial | Axial | Axial | Axial | |

| Fan qty. | 1 | 1 | 1 | 1 | 1 | ||

| Power | kW | 0.55 | 0.55 | 0.55 | 0.75 | 1.1 | |

| Air flow | m³/h | 8000 | 10000 | 10000 | 12000 | 16000 | |

| Location of air discharge | Side or top | Side or top | Side or top | Side or top | Top | ||

| Dimension (side/top) | L | mm | 1180 | 1180 | 1180 | 1180 | 1180 |

| W | mm | 730(1080) | 730(1080) | 730(1080) | 730(1080) | 1080 | |

| H | mm | 1870(1870) | 1870(1870) | 1870(1870) | 1870(1960) | 2055 | |

| Net weight | kg | 320 | 350 | 380 | 380 | 420 | |

| Operation weight | kg | 360 | 380 | 420 | 420 | 690 | |

| Noise | dB(A) | 69 | 69 | 70 | 71 | 74 | |

| Remarks: | 1. Cooling standard working conditions: ambient temperature 35℃DB/24℃WB; cold water inlet temperature 12℃, outlet temperature 7℃ 2. Heating standard working conditions I: ambient temperature 7℃DB/6CWB; cold water inlet temperature 40℃, outlet temperature 45℃ | ||||||

| Main protection measures | 1. High & low voltage protection 2. Anti-freezing protection 3. Temperature contr 4. Phase loss protection 5. High & low pressure protection 6. High pressure exhaust temperature protection 7. Built-in motor overheating protection 8. Over-current protection 9. Safe valve 10. Check valve | ||||||

| Additional options | Internal water pump and expansion tank, RS485 module, year-round cooling function, WIFI controller, spring shock absorber, rubber shock pad, etc. | ||||||

| Model | RLSFW20RD | RLSFW25RD | RLSFW30RD | RLSFW40RD | RLSFW45RD | ||

| Nominal cooling capacity | kW | 21.5 | 23.1 | 27 | 32 | 43 | |

| Cooling input power | kW | 7.5 | 7.9 | 9 | 10.4 | 13.3 | |

| EER | 2.87 | 2.92 | 3.00 | 3.08 | 3.23 | ||

| Running current | A | 11.4 | 12 | 13.7 | 15.8 | 20.2 | |

| Nominal heating capacity I | kW | 24.4 | 26.3 | 30 | 38.2 | 46.2 | |

| Heating input power I | kW | 7.4 | 7.9 | 9 | 10.3 | 13.2 | |

| COP I | 3.30 | 3.33 | 3.33 | 3.71 | 3.50 | ||

| Running current | A | 11.2 | 12.0 | 13.7 | 15.6 | 20.1 | |

| Nominal heating capacity II | kW | 17.8 | 19.2 | 21.9 | 27.9 | 33.8 | |

| Heating input power II | kW | 7.5 | 8.0 | 9.1 | 10.4 | 13.3 | |

| COP II | 2.39 | 2.41 | 2.41 | 2.69 | 2.54 | ||

| Running current | A | 11.3 | 12.1 | 13.8 | 15.8 | 20.2 | |

| Max. running current | A | 20.6 | 21.5 | 24 | 27 | 35 | |

| Cable diameter (copper wire distance ≤20 meters) | mm² | 3*6 2*4 | 3*6 2*4 | 3*6 2*4 | 3*6 2*4 | 3*10 2*6 | |

| Power voltage | 380V/3PH/50HZ | ||||||

| Compressor | Type | Hermetic scroll type | |||||

| Quantity | 1 | 1 | 1 | 1 | 1 | ||

| Start mode | Direct start | ||||||

| Refrigerant | Type | R410A/R407C | |||||

| Charge (kg) | 8.5. | 10 | 10.5 | 11.5 | 12 | ||

| Control | Electronic expansion valve (EXV) | ||||||

| Evaporator | Type | Stainless steel plate type | |||||

| Water pressure drop | kPa | 70-90 | 70-90 | 70-90 | 70-90 | 70-90 | |

| Water pipe dia. DN | DN32 | DN32 | DN40 | DN40 | DN40 | ||

| Water flow | m³/h | 3.4 | 3.6 | 4.3 | 5.0 | 6.7 | |

| Condenser type | Internally threaded copper tube & hydrophilic aluminum fins | ||||||

| Condenser fan | Fan type | Axial | Axial | Axial | Axial | Axial | |

| Fan qty. | 1 | 1 | 1 | 1 | 1 | ||

| Power | kW | 0.55 | 0.55 | 0.55 | 0.75 | 1.1 | |

| Air flow | m³/h | 8000 | 10000 | 12000 | 14000 | 16000 | |

| Location of air discharge | Side or top | Side or top | Side or top | Side or top | Top | ||

| Dimension (side/top) | L | mm | 1180 | 1180 | 1180 | 1180 | 1180 |

| W | mm | 730(1080) | 730(1080) | 730(1080) | 730(1080) | 1080 | |

| H | mm | 1870(1870) | 1870(1870) | 1870(1870) | 1870(1960) | 2055 | |

| Net weight | kg | 320 | 350 | 380 | 380 | 420 | |

| Operation weight | kg | 360 | 380 | 420 | 420 | 490 | |

| Noise | dB(A) | 69 | 69 | 70 | 71 | 78 | |

| Remarks: | 1. Cooling standard working conditions: ambient temperature 35℃DB/24℃WB; cold water inlet temperature 12℃, outlet temperature 7℃ 2. Heating standard working conditions I: ambient temperature 7℃DB/6CWB; hot water inlet temperature 40℃, outlet temperature 45℃ 3. Heating standard working conditions II: ambient temperature -12℃DB/-13.5CWB; outlet temperature 41℃ | ||||||

| Main protection measures | 1. High & low voltage protection 2. Anti-freezing protection 3. Temperature control 4. Phase loss protection 5. High & low pressure protection 6. High pressure exhaust temperature protection 7. Built-in motor overheating protection 8. Over-current protection 9. Safe valve 10. Check valve | ||||||

| Additional options | Internal water pump and expansion tank, RS485 module, year-round cooling function, WIFI controller, spring shock absorber, rubber shock pad, etc. | ||||||

Features

- Compressor High efficiency scroll compressor from well-known brands features low noise level and long service life.

- Evaporator Stainless steel plate heat exchangers used as evaporators come with small size, light weight, high heat transfer coefficient, and simple maintenance.

- Condenser The condenser is equipped with high efficiency internally threaded copper pipe and high quality aluminum. The copper tubes are mechanically bonded to aluminum fins, resulting in perfect combination between them. The optimized pipeline flow allows for the best heat transfer effect.

- Distribution Control Box Microcomputer control system adopts electrical elements from internationally well-known brands, enabling it to operate stably and reliably at ambient temperatures of -15 °C to 65 °C.

- Superior Quality Refrigeration Accessories Refrigeration accessories from well-known brands ensure reliable and stable operation.

- Special Purpose The air cooled scroll chiller can be equipped with a waste heat recovery unit to recover waste heat during cooling operation for supplying hot water for residential, catering, shopping malls, offices, etc.

- Safety Facilities Complete protection devices provide all-round protection to the scroll chiller, allowing for great operation safety. Protection devices include: high and low pressure protection, overload protection, ultra-low water temperature protection, anti-freezing protection, and water supply protection.

- Heat Recovery Type Modular Type Air Cooled Water Chiller and Heat pump (non-standard unit, please indicate when ordering) a. The heat recovery unit has functions of refrigeration and heating to provide domestic hot water. There are two types of heat recovery: 30% recovery and 100% recovery.

b. The cooling only unit can recover the originally discarded condensing heat while cooling in summer, and can also be cooled separately; the heat pump unit has three functions including cooling, heating, which can provide domestic hot water.

c. The comprehensive performance coefficient of the heat recovery unit is as high as 3.5 ~ 3.9. The addition of the heat recovery unit is equivalent to increasing the heat exchange area of the unit and enhancing the heat exchange effect, thereby reducing the energy consumption of the chilling unit. - Low Temperature Modular Type Air Cooled Water Chiller and Heat pump (non-standard unit, please specify when ordering) Adopting EVI scroll compressor and economizer, the scroll chiller can be used normally in low temperature environment, and greatly improve the heating efficiency of the unit in winter.

a. The compressor has added one gas filling port, the suction air of the unit is increased, the circulation flow is increased, the heat exchange on the condensing side is greatly increased, the heating capacity of the unit is increased by more than 30%, and the performance coefficient is also greatly improved.

b. In order to optimize the unit performance, the amount of refrigerant evaporated in the evaporator at low ambient temperatures is increased, which can effectively avoid the failure of complete evaporation of the refrigerant due to the poor evaporation effect.

c. Increase the enthalpy of the compressor by supplementing air, increasing the displacement of the compressor. This ensures the unit still runs stably at low ambient temperatures, and the compressor will not exceed the compression ratio.

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos