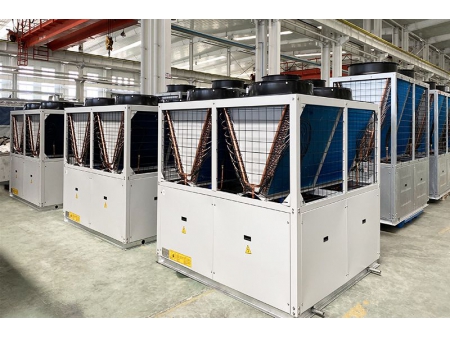

Modular Type Air Cooled Chiller and Heat Pump, 60kW-150kW

This product has been discontinued and removed from our shelves.

The modular air cooled chiller and heat pump is designed for cooling and heating operations in large commercial and industrial buildings. The chiller and heat pumps will often be installed in malls, hotels, hospitals, and office buildings. The machine set can be installed on the roofs, balconies, courtyards, and other suitable outdoor positions. The equipment does not need to be installed in a specially built water chiller machine room.

| Type | Modular | ||||||||

| Model - RLSFWM-B (RLSFWM (B)R) | 68 | 136 | 204 | 272 | 340 | 408 | 476 | ||

| Cooling capacity | kW | 68 | 136 | 204 | 272 | 340 | 408 | 476 | |

| Cooling input power | kW | 21.1 | 42.2 | 63.2 | 84.3 | 105.4 | 126.5 | 147.6 | |

| Running current | A | 41.2 | 82.4 | 123.6 | 164.8 | 206 | 247.2 | 288.4 | |

| Heating capacity | kW | 70 | 140 | 210 | 280 | 350 | 420 | 490 | |

| Heating power | kW | 22.1 | 44.1 | 66.2 | 88.2 | 110.3 | 132.4 | 154.4 | |

| Running current | A | 39.5 | 79 | 118.5 | 158 | 197.5 | 237 | 276.5 | |

| Max. running current | A | 48.2 | 96.4 | 144.6 | 192.8 | 241 | 289.2 | 337.4 | |

| Cable diameter (copper wire distance ≤20 meters) | mm2 | 3*16 2*10 | (3*16 2*10)*2 | (3*16 2*10)*3 | (3*16 2*10)*4 | (3*16 2*10)*5 | (3*16 2*10)*6 | (3*16 2*10)*7 | |

| Compressor | Type | Hermetic scroll type | |||||||

| Quantity | 2 | 4 | 6 | 8 | 10 | 12 | 14 | ||

| Power voltage | 3N-380V-50HZ | ||||||||

| Start mode | Direct start | ||||||||

| Refrigerant | Type | R410a/R22 | |||||||

| Charge (kg) | 11.5*2 | 11.5*4 | 11.5*6 | 11.5*8 | 11.5*10 | 11.5*12 | 11.5*14 | ||

| Control | Electronic expansion valve (EXV) | ||||||||

| Evaporator | Type | Shell & tube type | |||||||

| Water Pressure drop | kPa | 70 | |||||||

| Water pipe Dia. DN | DN50 | DN50*2 | DN50*3 | DN50*4 | DN50*5 | DN50*6 | DN50*7 | ||

| Water flow | m3/h | 11.7 | 23.4 | 35.1 | 46.8 | 58.5 | 70.2 | 81.9 | |

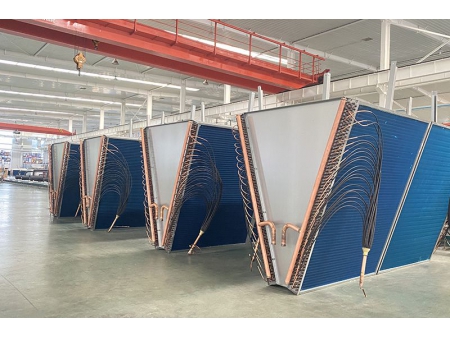

| Condenser type | Internally threaded copper tube & hydrophilic aluminum fins | ||||||||

| Dimension | L | mm | 2110 | 2110 | 2110 | 2110 | 2110 | 2110 | 2110 |

| W | mm | 1080 | 2160 | 3240 | 4320 | 5400 | 6480 | 7560 | |

| H | mm | 1870 | 1870 | 1870 | 1870 | 1870 | 1870 | 1870 | |

| Net weight | kg | 700 | 1400 | 2100 | 2800 | 3500 | 4200 | 4900 | |

| Operation weight | kg | 760 | 1520 | 2280 | 3040 | 3800 | 4560 | 5320 | |

| Noise level | dB(A) | 73 | 73 | 73 | 74 | 74 | 74 | 74 | |

| Main protection measures | 1. High & low voltage protection; 2. Anti-freezing protection; | ||||||||

| 3. Temperature control; 4. Owe anti-phase protection; | |||||||||

| 5. High & low pressure protection; 6. High pressure exhaust temperature protection; | |||||||||

| 7. Built-in motor overheating protection; 8. Over-current protection; | |||||||||

| 9. Safety valve; 10.Check valve; | |||||||||

| Remarks | 1. Cooling standard working conditions Ambient temperature 35℃DB/24℃WB Cold water inlet temperature: 12℃ Outlet temperature: 7℃ | ||||||||

| 2. Heating standard working conditions Ambient temperature: 7℃DB/6℃WB Cold water inlet temperature: 40℃ Outlet temperature: 45℃ | |||||||||

| Type | Modular | ||||||||

| Model - RLSFWM -B (RLSFWM -(B)R) | 136 | 272 | 408 | 544 | 680 | 816 | 952 | ||

| Cooling capacity | kW | 136 | 272 | 408 | 544 | 680 | 816 | 952 | |

| Cooling input power | kW | 42.2 | 84.3 | 126.5 | 168.6 | 210.8 | 253 | 295.1 | |

| Running current | A | 80.4 | 162.8 | 241.2 | 321.6 | 402 | 482.4 | 562.8 | |

| Heating capacity | kW | 140 | 280 | 420 | 560 | 700 | 840 | 980 | |

| Heating power | kW | 44.1 | 88.2 | 132.4 | 176.5 | 220.6 | 264.7 | 308.8 | |

| Running current | A | 76.4 | 150.8 | 229.2 | 305.6 | 382 | 458.4 | 534.8 | |

| Max. running current | A | 96.4 | 195.3 | 289.2 | 385.6 | 482 | 578.4 | 674.8 | |

| Cable diameter (copper wire distance ≤20 meters) | mm2 | 3*35 2*16 | (3*35 2*16)*2 | (3*35 2*16)*3 | (3*35 2*16)*4 | (3*35 2*16)*5 | (3*35 2*16)*6 | (3*35 2*16)*7 | |

| Compressor | Type | Hermetic scroll type | |||||||

| Quantity | 4 | 8 | 12 | 16 | 20 | 24 | 28 | ||

| Power voltage | 3N-380V-50HZ | ||||||||

| Start mode | Direct Start | ||||||||

| Refrigerant | Type | R410a/R22 | |||||||

| Charge (kg) | 11.5*4 | 11.5*8 | 11.5*12 | 11.5*16 | 11.5*20 | 11.5*24 | 11.5*28 | ||

| Control | Electronic expansion valve (EXV) | ||||||||

| Evaporator | Type | Shell & tube type | |||||||

| Water Pressure drop | kPa | 70 | |||||||

| Water pipe Dia.DN | 65 | 65*2 | 65*3 | 65*4 | 65*5 | 65*6 | 65*7 | ||

| Water flow | m3/h | 23.4 | 46.8 | 70.2 | 93.6 | 117.0 | 140.4 | 163.7 | |

| Condenser type | Internally threaded copper tube & hydrophilic aluminum fins | ||||||||

| Dimension | L | mm | 2110 | 2110 | 2110 | 2110 | 2110 | 2110 | 2110 |

| W | mm | 2160 | 4320 | 6480 | 8640 | 10800 | 12960 | 15120 | |

| H | mm | 1870 | 1870 | 1870 | 1870 | 1870 | 1870 | 1870 | |

| Net weight | kg | 1360 | 2720 | 4080 | 5440 | 6800 | 8160 | 9520 | |

| Operation weight | kg | 1480 | 2960 | 4440 | 5920 | 7400 | 8880 | 10360 | |

| Noise level | dB(A) | 73 | 73 | 73 | 74 | 74 | 74 | 74 | |

| Main protection measures | 1. High & low voltage protection; 2. Anti-freezing protection; | ||||||||

| 3. Temperature control; 4. Owe anti-phase protection; | |||||||||

| 5. High & low pressure protection; 6. High pressure exhaust temperature protection; | |||||||||

| 7. Built-in motor overheating protection; 8. Over-current protection; | |||||||||

| 9. Safety valve; 10. Check valve; | |||||||||

| Remarks | 1. Cooling standard working conditions Ambient temperature: 35℃DB/24℃WB Cold water inlet temperature: 12℃ Outlet temperature: 7℃ | ||||||||

| 2. Heating standard working conditions Ambient temperature: 7℃DB/6℃WB Cold water inlet temperature: 40℃ Outlet temperature: 45℃ | |||||||||

| Type | Modular | ||||||||

| Model | RLSFWM68 | RLSFWM136 | RLSFWM204 | RLSFWM272 | RLSFWM340 | RLSFWM408 | RLSFWM476 | ||

| Nominal Cooling capacity | kW | 68 | 136 | 204 | 272 | 340 | 408 | 476 | |

| Input Power | kW | 21.1 | 42.2 | 63.2 | 84.3 | 105.4 | 126.5 | 147.6 | |

| Running Current | A | 41.2 | 82.4 | 123.6 | 164.8 | 206 | 247.2 | 288.4 | |

| Nominal heating capacity I | kW | 78 | 156 | 234 | 312 | 390 | 468 | 546 | |

| Input power | kW | 22.3 | 44.7 | 67 | 89.4 | 111.7 | 134 | 156.4 | |

| Running current | A | 41.6 | 79 | 118.5 | 158 | 197.5 | 237 | 276.5 | |

| Nominal heating capacity II | kW | 57 | 114 | 171 | 228 | 285 | 342 | 399 | |

| Input power | kW | 21.3 | 42.6 | 63.9 | 85.2 | 106.5 | 127.8 | 149.1 | |

| Running current | A | 41.6 | 83.2 | 124.8 | 166.4 | 208 | 249.6 | 291.2 | |

| Max. running current | A | 50.4 | 96.4 | 144.6 | 192.8 | 241 | 289.2 | 337.4 | |

| Cable diameter (copper wire distance ≤20 meters) | mm2 | 3*16 2*10 | (3*16 2*10)*2 | (3*16 2*10)*3 | (3*16 2*10)*4 | (3*16 2*10)*5 | (3*16 2*10)*6 | (3*16 2*10)*7 | |

| Compressor | Type | Hermetic scroll type | |||||||

| Quantity | 2 | 4 | 6 | 8 | 10 | 12 | 14 | ||

| Power voltage | 3N-380V-50HZ | ||||||||

| Starting mode | Starting mode | ||||||||

| Refrigerant | Type | R410a/R22 | |||||||

| Charge (kg) | 11*2 | 11*4 | 11*6 | 11*8 | 11*10 | 11*12 | 11*14 | ||

| Control device | Electronic expansion valve | ||||||||

| Evaporator | Type | Shell & tube type | |||||||

| Water Pressure drop | kPa | 70 | |||||||

| Water pipe Dia.DN | DN50 | DN50*2 | DN50*3 | DN50*4 | DN50*5 | DN50*6 | DN50*7 | ||

| Water flow | m3/h | 10.66 | 21.32 | 31.98 | 42.64 | 53.30 | 63.96 | 74.62 | |

| Condenser type | Internally threaded copper tube & hydrophilic aluminum fins | ||||||||

| Dimension | L | mm | 2110 | 2110 | 2110 | 2110 | 2110 | 2110 | 2110 |

| W | mm | 1080 | 2160 | 3240 | 4320 | 5400 | 6480 | 7560 | |

| H | mm | 1870 | 1870 | 1870 | 1870 | 1870 | 1870 | 1870 | |

| Net weight | kg | 700 | 1400 | 2100 | 2800 | 3500 | 4200 | 4900 | |

| Running weight | kg | 760 | 1520 | 2280 | 3040 | 3800 | 4560 | 5320 | |

| Noise level | dB(A) | 73 | 73 | 73 | 74 | 74 | 74 | 74 | |

| Main protection measures | 1. High & low voltage protection; 2. Anti-freezing protection; | ||||||||

| 3. Temperature control; 4. Owe anti-phase protection; | |||||||||

| 5.High & low pressure protection; 6.High pressure exhaust temperature protection; | |||||||||

| 7. Built-in motor overheating protection; 8. Over-current protection; | |||||||||

| 9. Safety valve; 10.Check valve; | |||||||||

| Remarks | 1. Cooling standard working conditions Ambient temperature: 35℃DB/24℃WB Cold water inlet temperature: 12℃ Outlet temperature: 7℃ | ||||||||

| 2. Heating standard working conditions Ambient temperature: 7℃DB/6℃WB Cold water inlet temperature: 40℃ Outlet temperature: 45℃ | |||||||||

| Type | Modular | ||||||||

| Model | RLSFWM136 | RLSFWM272 | RLSFWM408 | RLSFWM544 | RLSFWM680 | RLSFWM816 | RLSFWM952 | ||

| Nominal cooling capacity | kW | 136 | 272 | 408 | 544 | 680 | 816 | 952 | |

| Cooling input power | kW | 42.2 | 84.4 | 126.6 | 168.8 | 211 | 253.2 | 295.4 | |

| Running current | A | 82.4 | 164.8 | 247.2 | 329.6 | 412 | 494.4 | 576.8 | |

| Nominal heating capacity I | kW | 156 | 312 | 468 | 624 | 780 | 936 | 1092 | |

| Heating input power | kW | 44.7 | 89.4 | 134 | 178.7 | 223.4 | 268.1 | 312.9 | |

| Running current | A | 80.4 | 160.8 | 241.2 | 321.6 | 402 | 482.4 | 562.8 | |

| Nominal heating capacity II | kW | 114 | 228 | 342 | 456 | 570 | 684 | 798 | |

| Heating input power | kW | 42.6 | 85.2 | 127.8 | 170.4 | 213 | 255.6 | 298.2 | |

| Running current | A | 83.2 | 166.4 | 249.6 | 332.8 | 416 | 499.2 | 582.4 | |

| Max. running current | A | 96.4 | 192.8 | 289.2 | 385.6 | 482 | 578.4 | 674.8 | |

| Cable diameter (copper wire distance ≤20 meters) | mm2 | 3*35 2*16 | (3*35 2*16)*2 | (3*35 2*16)*3 | (3*35 2*16)*4 | (3*35 2*16)*5 | (3*35 2*16)*6 | (3*35 2*16)*7 | |

| Power voltage | 3N-380V-50HZ | ||||||||

| Compressor | Type | Hermetic scroll type | |||||||

| Quantity | 4 | 8 | 12 | 16 | 20 | 24 | 28 | ||

| Starting mode | Direct start | ||||||||

| Refrigerant | Type | R410a/R22 | |||||||

| Charge (kg) | 11.5*4 | 11.5*8 | 11.5*12 | 11.5*16 | 11.5*20 | 11.5*24 | 11.5*28 | ||

| Control device | Electronic expansion valve | ||||||||

| Evaporator | Shell & tube type | ||||||||

| Water Pressure drop | kPa | 70 | |||||||

| Water pipe Dia.DN | DN65 | DN65*2 | DN65*3 | DN65*4 | DN65*5 | DN65*6 | DN65*7 | ||

| Water flow | m3/h | 23.39 | 46.78 | 70.18 | 93.57 | 116.96 | 140.35 | 163.74 | |

| Condenser type | Internally threaded copper tube & hydrophilic aluminum fins | ||||||||

| Dimension | L | mm | 2110 | 2110 | 2110 | 2110 | 2110 | 2110 | 2110 |

| W | mm | 2160 | 4320 | 6480 | 8640 | 10800 | 12960 | 15120 | |

| H | mm | 1870 | 1870 | 1870 | 1870 | 1870 | 1870 | 1870 | |

| Net weight | kg | 1360 | 2720 | 4080 | 5440 | 6800 | 8160 | 9520 | |

| Running weight | kg | 1480 | 2960 | 4440 | 5920 | 7400 | 8880 | 10360 | |

| Noise level | dB(A) | 73 | 73 | 73 | 74 | 74 | 74 | 74 | |

| Main protection measures | 1. High &low voltage protection; 2. Anti-freezing protection; | ||||||||

| 3. Temperature control; 4. Owe anti-phase protection; | |||||||||

| 5. High & low pressure protection; 6. High pressure exhaust temperature protection; | |||||||||

| 7. Built-in motor overheating protection; 8. Over-current protection; | |||||||||

| 9. Safety valve; 10.Check valve; | |||||||||

| Remarks: | 1. Cooling standard working conditions Ambient temperature: 35℃DB/24℃WB Cold water inlet temperature: 12℃ Outlet temperature: 7℃ | ||||||||

| 2. Heating standard working conditions Ambient temperature: 7℃DB/6℃WB Cold water inlet temperature: 40℃ Outlet temperature: 45℃ | |||||||||

- High and low voltage protection

- Anti-freezing protection

- Temperature control

- Power anti-phase protection

- High & low pressure protection

- High pressure exhaust temperature protection

- Built-in motor overheating protection

- Over-current protection

- Safety valve

- Check valve

Notes

Cooling: Ambient temperature DB 35 ℃, WB 24 ℃ water in/out 12/7 ℃

Heating: Ambient temperature DB 7 ℃, WB 6 ℃ water in/out temperature 40/45 ℃

Units above can realize 1-7 units' modular connection and can control energy-regulation automatically

Sound pressure measured at a distance of 1 m and a height of 1.5 m above the ground in an open field Built-in water pump and expansion tank are optional.

- Easy installation and space saving. No need to be equipped with cooling water pump, cooling tower, or other auxiliary equipment. No need for a large amount of materials and installation fees.

- One machine has dual uses. It can work as heating supply or cooling machine with the same equipment.

- Modular type system design. Every cooling systems runs independently and backs up the other pieces. Failure of any of cooling loop will not affect normal operation of other loops.

- The complete machine set can be assembled onsite. Standard modules are lightweight and take up minimal space.

- Free combination among modules can be achieved according to client's demands and cooling/heating needs.

- While the machine set is starting up, computer controls the compressors to start up in order, which reduces the current impact to power the network.