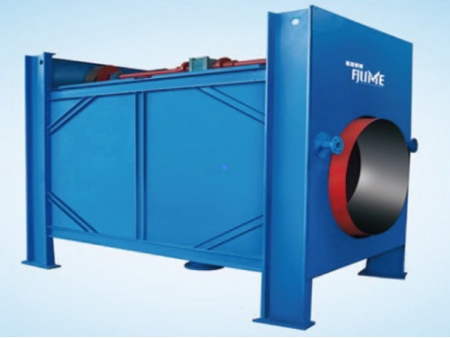

Drum Hydrapulper

Features

1. The drum hydrapulper is designed to not damage the fibers: soft pulping mechanism to protect the fibers and guarantee quality.

2. Does not break up impurities: maintains the integrity of the impurities.

3. Minimum complementary conditions: reduces downtime, saves money

4. Remarkable energy saving: energy consumption is only 1/2-1/3 of traditional hydrapulpers.

5. Three in one, save cost: combines pulping, roughing, impurities removal in one.

Application

Waste paper pulp machine production line; Corrugated paper making production line

Fluting paper pulp making production line; Coated White Board Paper production line

Testliner paper making production line; Toilet/tissue paper making production line

Kraft paper making machine line; Paper coating machine line

Napkin paper machine line; OCC line

| Model | |||||||||

| Equipment diameter(mm) | 200 | 225 | 250 | 275 | 300 | 325 | 350 | 375 | 400 |

| Capacity(T/D) | 30-50 | 50-80 | 80-160 | 140-200 | 180-240 | 220-330 | 320-450 | 450-650 | 600-900 |

| Motor Power(kw) | 55 | 75 | 132 | 160 | 250 | 355 | 500 | 630 | 2×500 |

| Working temperature(℃) | 40--90 | ||||||||

| Consistency(%) | 14-18 | ||||||||