CNC Hydraulic Press Brake

The CNC hydraulic press brake, also known as an electro-hydraulic synchronous CNC bending machine, is used to bend a variety of plates, including stainless steel plates, carbon steel plates, copper plates, aluminum plates, and more. This machine features a high precision, smooth functions, and an excellent synchronization performance, making it ideal for use with kitchen ware, bathroom accessories, advertisement boards, light-fixtures and hardware, electric equipment and other metal manufacturing.

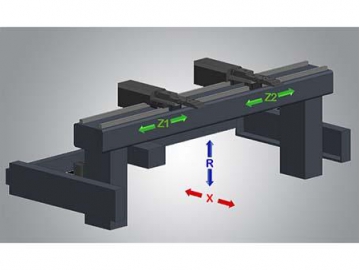

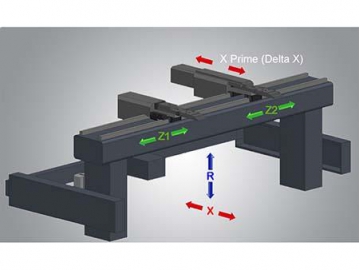

Features- The machine body uses a rigid torsion bar design, electro-hydraulic servo valve, and a linear scale to achieve a closed loop control, and a fast, precise motion for sliding block feedback, a high synchronization performance and a high bending accuracy. The repeated positioning error is less than 0.02 mm.

- The body structure undergoes an annealing treatment to eliminate mechanical internal stress and remain durable.

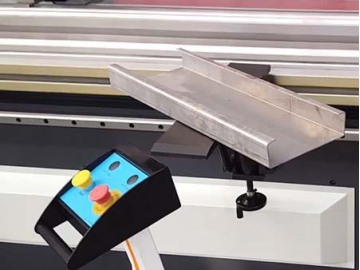

- The metal plate stopper is designed with several plate stopper screws.

- The hydraulic system features an integral control system to make it easier for pipe installation and prevent oil leaks.

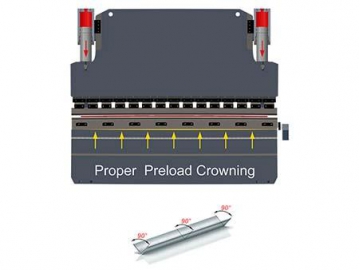

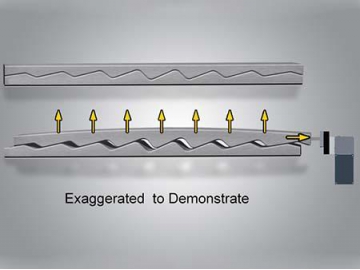

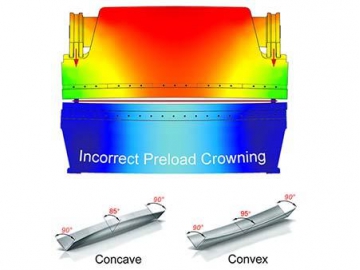

- The machine is equipped with an automatic hydraulic compensation mechanism for deflection, removing any risk of impact caused by sliding block deformation.

- Users can choose a hydraulic structure or mechanical structure to move the worktable for positioning compensation, and an adjustable, easy to use forward moving support can be equipped upon request.

| Models | Nomal Pressure (Kn) | Length of Table (mm) | Distance Between Housing (mm) | Throat Depth (mm) | Stroke (mm) | Open Hight (mm) | Main Motor (Kw) | Weight (t) | Overall Dimensions (L W H) (mm) |

| 63/2500 | 630 | 2500 | 2000 | 320 | 150 | 380 | 5.5 | 5 | 28751650*2350 |

| 63/3200 | 630 | 3200 | 2700 | 320 | 150 | 380 | 5.5 | 5.5 | 3800*1650*2450 |

| 100/3200 | 1000 | 3200 | 2700 | 400 | 180 | 440 | 7.5 | 7.5 | 3810*1750*2530 |

| 125/3200 | 1250 | 3200 | 2700 | 400 | 180 | 440 | 7.5 | 8.2 | 3820*1800*2530 |

| 125/4000 | 1250 | 4000 | 3200 | 400 | 180 | 440 | 7.5 | 9 | 4600*1800*2580 |

| 160/3200 | 1600 | 3200 | 2700 | 400 | 180 | 450 | 11 | 10.8 | 3830*1870*2560 |

| 160/4000 | 1600 | 4000 | 3200 | 400 | 180 | 450 | 11 | 11.5 | 4610*1920*2700 |

| 200/3200 | 2000 | 3200 | 2700 | 400 | 180 | 450 | 11 | 12.5 | 3900*1920*2560 |

| 200/4000 | 2000 | 4000 | 3200 | 400 | 180 | 450 | 11 | 13.8 | 4620*1950*2700 |

| 200/6000 | 2000 | 6000 | 4800 | 400 | 180 | 480 | 11 | 18.5 | 6080*1950*2900 |

| 250/3200 | 2500 | 3200 | 2700 | 400 | 200 | 480 | 15 | 15 | 3900*2150*2950 |

| 250/4000 | 2500 | 4000 | 3200 | 400 | 200 | 480 | 15 | 16.5 | 4080*2150*3000 |

| 250/5000 | 2500 | 5000 | 4000 | 400 | 250 | 560 | 15 | 17.5 | 5080*2200*3250 |

| 250/6000 | 2500 | 6000 | 4800 | 400 | 250 | 560 | 15 | 20 | 6080*2200*3400 |

| 300/4000 | 3000 | 4000 | 3200 | 400 | 250 | 560 | 22 | 19 | 4080*2200*3200 |

| 300/5000 | 3000 | 5000 | 4000 | 400 | 250 | 560 | 22 | 21 | 5100*2200*3300 |

| 300/6000 | 3000 | 6000 | 4800 | 400 | 250 | 560 | 22 | 24 | 6200*2200*3500 |

| 400/4000 | 4000 | 4000 | 3200 | 400 | 320 | 630 | 30 | 25 | 4100*2400*3500 |

| 400/5000 | 4000 | 5000 | 4000 | 500 | 320 | 630 | 30 | 28 | 5200*2600*3700 |

| 400/6000 | 4000 | 6000 | 4800 | 500 | 320 | 630 | 30 | 38 | 6200*2650*4800 |

| 500/4000 | 5000 | 4000 | 3200 | 600 | 320 | 630 | 37 | 40 | 4200*2800*4600 |

| 500/5000 | 5000 | 5000 | 4000 | 600 | 320 | 630 | 37 | 45 | 5200*2800*4900 |

| 500/6000 | 5000 | 6000 | 4800 | 600 | 320 | 630 | 37 | 50 | 6200*2800*5200 |

| 600/5000 | 6000 | 5000 | 4000 | 600 | 320 | 630 | 45 | 58 | 5200*3000*5300 |

| 600/6000 | 6000 | 6000 | 4800 | 600 | 320 | 630 | 45 | 63 | 6200*3000*5600 |

| 800/5000 | 8000 | 5000 | 4000 | 700 | 350 | 800 | 55 | 75 | 5200*3500*5600 |

| 800/6000 | 8000 | 6000 | 4800 | 700 | 350 | 800 | 55 | 85 | 6200*3500*5800 |

| 1000/6000 | 10000 | 6000 | 4800 | 700 | 400 | 800 | 55 | 105 |

Hydraulic system: BOSCH Germany

Servo motor and drive: ESTUN Nan Jing

Numerical Control System: DELEM Netherland, ESA Italy, CYBELEC Switzerland

Liner scale: HEIDENHAIN, GIVI Italy

Ball screw and liner guide: HIWIN Taiwan

electrical apparatus element: SCHNEIDER France