Air-Cooled Laser Welding Machine

- Laser wavelength 1080nm

- Welding speed 0-20m/min (intelligent adjustable)

- Cooling method air cooling

- Machine weight 54kg

The air-cooled handheld laser welding machine offers core advantages: efficient heat dissipation, portable flexibility, and multi-scenario adaptability. This equipment utilizes fiber laser technology, with power covering 700W-2000W, a spot diameter of ≤0.2mm, and a heat-affected zone (HAZ) of <0.5mm. The weld strength is comparable to the base material, and the surface is smooth with no oxidation. Its integrated air-cooled design reduces the equipment weight to 54kg and volume to <0.3m³, supporting single-person transport and vehicle-mounted operations, making it suitable for complex scenarios like workshops, construction sites, and outdoors. Combined with intelligent preset parameters and a human-machine interactive touch screen, novice operators can get started with just 1 hour of training. It achieves a welding speed of 2-10cm/s, boosting efficiency by over 3 times compared to traditional arc welding. It is particularly ideal for demanding fields such as automotive repair, metal processing, and construction installation, serving as a benchmark choice for industrial-grade portable welders.

Stainless steel, aluminum alloy, copper, brass, galvanized sheet, nickel-plated parts, and dissimilar metals such as copper-aluminum composites, steel-aluminum hybrid structures, etc.

- Stainless steel plate laser welding

- Stainless steel guardrail laser welding

- Metal part laser welding

- Aluminum plate laser welding

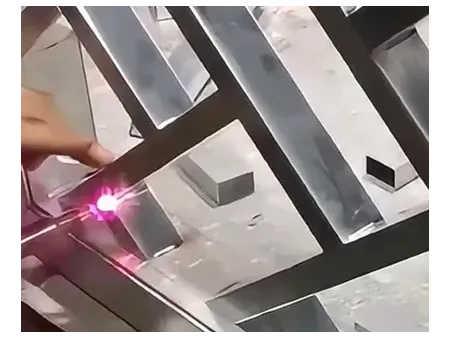

- Stainless steel square tube laser welding

- Stainless steel plate laser welding

- Stainless steel tee pipe fitting laser welding

- Metal laser welding

- Technical Data

- Configuration

- Laser type fiber laser

- Laser wavelength 1080nm

- Laser power 700W, 1000W, 1500W, 2000W

- Welding thickness 0.1-6mm (stainless steel/aluminum alloy)

- Laser spot size ≤0.2mm (focus adjustable)

- Welding speed 0-20m/min (intelligent adjustable)

- Working mode continuous welding/fish scale welding/intermittent welding

- Interface QBH

- Scanning width 6mm

- Fiber length 10m

- Welding head weight 660g

- Power supply 220V/50Hz ±10%, total power ≤3kW

- Cooling method air cooling

- Machine dimensions 220×405×535mm, 215×530×420mm (wire feeder)

- Package size 700×750×620mm

- Machine weight 54kg

- Package weight 65kg

Laser source

We provide renowned domestic and international brand laser sources for our equipment, such as Raycus, JPT, MAX, SUPER, and IPG; these feature high pump conversion efficiency, low power consumption, and excellent beam quality.

QBH handheld welding head

Supports seamless switching between welding, cleaning, and cutting modes. The gun head can rotate 360°, and coupled with replaceable gas nozzles (e.g., 30°, 60°, 90° nozzles), it easily handles complex positions like deep cavities and corners, achieving precise welding at any angle.

Touch screen

Provides a high-resolution display interface, supporting real-time parameter monitoring and operation feedback, ensuring precise control over key parameters such as laser power, frequency, and energy; built-in multi-language options (e.g., Chinese, English, etc.) adapt to global user needs and lower the operating threshold.

Safety goggles

Specifically designed for fiber laser wavelengths (e.g., 1064nm, 1070-1100nm), with an Optical Density (OD) reaching OD4 to OD7 , effectively attenuating laser energy to below safe thresholds. They balance clear vision with safety protection and reduce operational fatigue.

Tool box

A tool set is provided free with the equipment, with hex key tools, copper nozzles, protective lenses, etc., separately packaged to prevent transport wear and tear, and for clear visibility and improved operational efficiency.

Copper nozzles

Made from high-purity red copper or tungsten-copper alloy, with electrical conductivity up to 98% IACS and a melting point of 1083℃. They can withstand high-temperature oxidation during continuous welding, extending their service life by over 30% compared to ordinary alloy nozzles.

Protective lenses

Made from JGS1 quartz or ZnSe zinc selenide, with light transmittance ≥99.8% and laser damage threshold >15J/cm². They are suitable for high-power equipment above 2000W, reducing energy loss. Double-sided anti-reflective coating reduces reflectivity to below 0.2%, preventing secondary light pollution.

Wire feeder

Supports wire diameters from 0.8-1.6mm with stepless speed adjustment from 0-20m/min and an error of ±1%. It is compatible with various welding wire materials such as aluminum, stainless steel, and copper.

- Protective Lenses

- Copper Nozzles

- Welding Wire