HDPE Siphonic Roof Drainage System

Our HDPE siphonic roof drainage system is designed to guarantee maximum drainage performance with the lowest levels of water accumulation on the roof. By means of siphon action which generates pressure flow in the pipe, the system can quickly discharge the rainwater on the roof.

HDPE pipes and fittings used in this rainwater drainage system come with smaller diameter than those in conventional gravity discharge system. They can be installed horizontally without having to keep an inclined angle.

Applications

The siphonic system is widely used for roof rainwater drainage in high-rise buildings, shopping malls, supermarkets, railway stations, airports, mines, artistic and sports buildings, etc.

HDPE pipes and fittings for siphonic roof drainage system can bear a certain negative pressure. Kingbull is one of the rare enterprises in China which can offer full range of siphonic HDPE pipes, fittings and accessories.

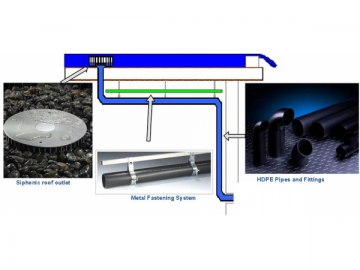

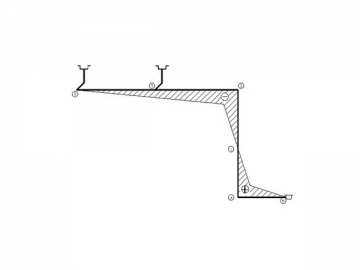

The system is mainly comprised of three parts (as shown below):

1. Siphonic roof outlet2. HDPE Pipes and Fittings

3. Metal Fastening System

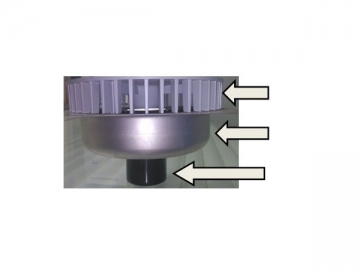

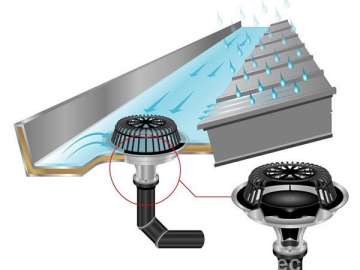

Siphonic Roof Outlet

1) Principle

As rain falls, rainwater enters the outlet from its side. When the rainwater on the roof is accumulated to a certain height, anti-eddy unit in the outlet will block the entry of air into the system and at the same time stop a vortices forming, thus enabling the rainwater to enter the drain pipe stably. As air is stopped entering the pipe, siphonage is formed.

The connector of our roof outlet is made of HDPE. It can be directly connected to the system pipe and ensure high air tightness, making it easy to form a stable siphonic drainage.

2)Construction

Kingbull’s roof outlets for siphonic roof drainage system are composed of leaf guard, outlet bowl and connector (tail),

① Leaf guard: Die cast aluminum alloy coated with fluorocarbon paint, providing high resistance to acid and alkali and ensuring an outdoor service life of up to 20 years.

② Outlet Bowl: It is fabricated using 304 stainless steel imported from Japan. Integrally molded by two stretching processes, it comes with smooth and clean surface and high strength.

③ Connector (Tail pipe): One-piece injection molding using HDPE, ensuring smooth inner face with small flow resistance.

Note: If the outlet is made of cast iron or steel, it requires clamp connection to the pipe. In this case, air tightness can not be guaranteed, thus leading to water leakage. (as shown below)

Clamp Connection

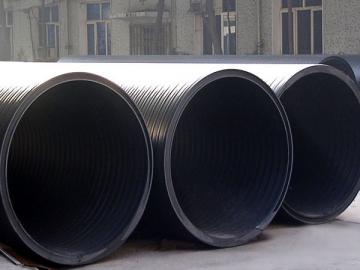

HDPE Drainage Pipes

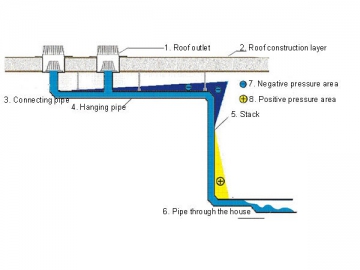

Siphonic roof drainage system will generate negative pressure during work, so it is required that the pipes used in the system has to be able to bear a certain negative pressure. The pictures below show the pressure state in pipe.

1. Roof outlet

2. Roof construction layer

3. Connecting pipe

4. Hanging pipe

5. Stack

6. Pipe through the house

7. Negative pressure area

8. Positive pressure area

Currently, Kingbull’s whole set of HDPE pipes for Siphonic system have passed the negative pressure (-0.08Mpa) test. We are the only enterprise in China to realize this.

We use PE100 HDPE pipes which come with following advantages:

a. Higher rigidity, larger negative pressure bearing capacity, safer system running;

b. Better resistance to environmental stress cracking, longer service life;

Specifications: 11 options from dn50 to dn315

Fittings

45° Elbow 91.5°(88.5°) Elbow 90° Tee with Screw-on Cover 45° Elbow 90° Elbow with long tail Eccentric Reducer Enhanced Electro-weld Sleeve Coupling Long Eccentric Reducer Siophonic Roof Outlet in a Concrete Slab Roof Siophonic Roof outlet in a Steel Profile Roof Deck Siophonic Roof outlet in a Steel Profile Roof Deck 45° Tee

Advantages of Kingbull HDPE Pipes and Fittings

Production capacity: Kingbull uses self produced HDPE drainage pipes and fittings.

Pressure bearing capacity: Our PE100, PN6 HDPE pipes feature high pressure bearing capacity. Nominal pressure is 0.6Mpa. They comply with the standards of EN1519-1 and ISO 8770.

Molding method: Our HDPE pipes under dn200 are injection molded, ensuringhigh pressure bearing capacity and small flow resistance.

Compatibility: All products from Kingbull are independently developed and manufactured, thus ensuring excellent system compatibility. In addition, the design software that we use works based on the parameters of our own pipes and fittings. So, it is sure to form stable siphonic action.

4. Metal Fastening System

Fasteners are often used in pipe installation. They must have specific strength which can withstand the weight of pipe with full flow and force from high speed flow. And they should ensure the HDPED pipes will not deform as ambient temperature changes.

Our metal fastening parts are manufactured from cold rolled steel. Their zinc coatings have passed strict acid mist test, ensuring high longevity.

C Profile Support Rail Clamp For Steel Square Pipe Connection Piece For C Profile Mounting Plate For the Stack Pipe Mounting Plate For Horizontal Pipe Pipe Bracket for 250-315mm Pipe Used with Pluviafix C Profile Support Rail Pipe Bracket for Guide and Anchor Point Stack Pipe Bracket G 12 Stack Pipe Bracket G1 Roof Outlet Spanner Square Steel Pipe Steel Square Pipe Connection Piece Tension Wedge for Sliding and Anchor Bracket