Metallized Polypropylene Film Capacitor, CBB65B Series

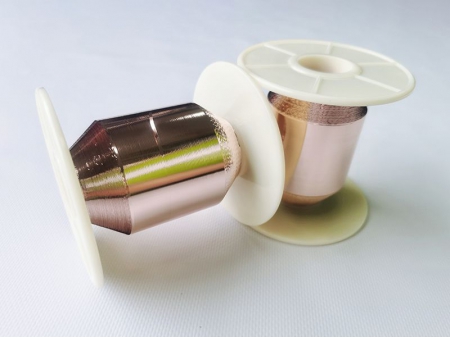

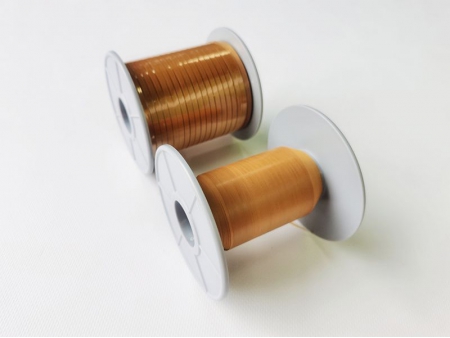

The CBB65B series metallized polypropylene film capacitor uses a thin layer of polypropylene film as the dielectric and adds metallic coatings to both of its sides via a process known as vacuum coating. The wound core then is potted in epoxy before being packed into an oval-shaped aluminum case. Known for its excellent self-healing capability and minimized power loss, the metallized polypropylene film capacitor delivers a consistent capacitance and is able to withstand high voltage.

Features

This metallized film capacitor dissipates heat quickly thanks to its large surface area. Built-in explosion-proof feature and bleeder resistor secures maximum safety during use, adding also to the excellent self-healing capability of the film cap. Built to tight conductance tolerance, our metallized polypropylene film capacitor ensures its short-circuit current does not override the limit, making it suitable for use on the metal halide lamp.

Uses

Used as either starting capacitor or running capacitor for 50/60HZ single phase AC motors installed in air conditioners, refrigerators, washing machines, among other home appliances.

In air conditioners, refrigerators, power generators, lamps and wherever the motor needs a power boost, model SF215 metallized polypropylene film capacitor is the ideal choice for use as either a running capacitor or a starting capacitor. Using a reinforced layer of polypropylene film as the dielectric, this metallized film cap has its core part wound up by a high-speed winding machine before being packed into an aluminum case.

The addition of refined castor oil to the capacitor’s surface gives the entire assembly the ability to resist high temperature and maintain a high vacuum level within the case, all of which makes for an extended service life. This metallized polypropylene film capacitor is an explosion-proof design, making it suitable for use in environments rife with opportunities for fire or explosion.

Performance Standard: GB3667.1-2005

Capacitance Tolerance: ±5%

Insulation Resistance: ≥3000s

Loss Tangent: tgδ≤0.002 (50Hz~100Hz)

Capacitance, Voltage and Size

| Nominal Capacitance µF | Voltage VAC | Size | ||

| 370 | D | W | H | |

| 5 | 31 | 52 | 55 | |

| 7.5 | 65 | |||

| 10 | ||||

| 12.5 | 90 | |||

| 15 | 100 | |||

| 5 | 440 | 45 | 71 | 65 |

| 7.5 | 75 | |||

| 10 | ||||

| 12.5 | 100 | |||

| 15 | ||||

| 25 | 370 | 90 | ||

| 35 | 100 | |||

| 25 | 440 | 90 | ||

| 35 | 100 | |||

| 5/35 | 370 | 110 | ||

| 5/40 | ||||

| 5/45 | 440 | 120 | ||

| 5/35 | 110 | |||

| 5/40 | 120 | |||

| 5/45 | ||||

Performance Standard: GB3667.1-2005

Capacitance Tolerance: ±5%

Insulation Resistance: ≥3000S

Loss Tangent: tgδ≤0.002(50Hz~100Hz)

Capacitance, Voltage and Size

| Nominal Capacitance µF | Voltage VAC | Size | ||

| 370 | D | W | H | |

| 5 | 31 | 52 | 55 | |

| 7.5 | 65 | |||

| 10 | ||||

| 12.5 | 90 | |||

| 15 | 100 | |||

| 5 | 440 | 45 | 71 | 65 |

| 7.5 | 75 | |||

| 10 | ||||

| 12.5 | 100 | |||

| 15 | ||||

| 25 | 370 | 90 | ||

| 35 | 100 | |||

| 25 | 440 | 90 | ||

| 35 | 100 | |||

| 5/35 | 370 | 110 | ||

| 5/40 | ||||

| 5/45 | 440 | 120 | ||

| 5/35 | 110 | |||

| 5/40 | 120 | |||

| 5/45 | ||||

Performance Standard: GB3667.1-2005

Capacitance Tolerance: ±5%

Insulation Resistance: ≥3000S

Loss Tangent: tgδ≤0.002(50Hz~100Hz)

Capacitance, Voltage and Size

| Nominal Capacitance µF | Voltage VAC | Size | ||

| 370 | D | W | H | |

| 5 | 31 | 52 | 55 | |

| 7.5 | 65 | |||

| 10 | ||||

| 12.5 | 90 | |||

| 15 | 100 | |||

| 5 | 440 | 45 | 71 | 65 |

| 7.5 | 75 | |||

| 10 | ||||

| 12.5 | 100 | |||

| 15 | ||||

| 25 | 370 | 90 | ||

| 35 | 100 | |||

| 25 | 440 | 90 | ||

| 35 | 100 | |||

| 5/35 | 370 | 110 | ||

| 5/40 | ||||

| 5/45 | 440 | 120 | ||

| 5/35 | 110 | |||

| 5/40 | 120 | |||

| 5/45 | ||||