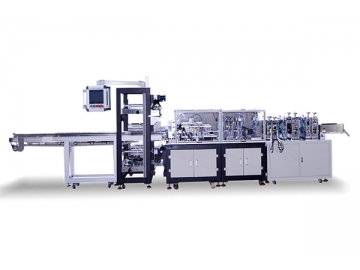

Horizontal Form Fill and Seal Machine for Plastic Cups

The horizontal form fill and seal machine for plastic cups is well received by the manufacturer of yogurt, milk, beverage, cream, cheese, seasoning, ice cream, etc.

Machine Construction

1. Drive and traction system

The drive and traction system includes servo motor, reduction box, linear stepping system, transmission chain, positioning device, etc.

2. Automatic preheating system

The preheating is controlled by the pneumatic actuator. The newly developed preheating system for the horizontal form fill and seal machine is composed of guiding unit, heating unit, and preheating panel.

3. Molding system

Our molding system contains mould, film stretching device, air blowing device, cooling system, and more.

4. Filling system

The filling system with metering device for the plastic cup filling and sealing machine includes silo, liquid level controller, two-way pneumatic valve, and pneumatically operated piston for fixed volume liquid filling. Equipped with special system for paste, the horizontal form fill and seal machine eliminates material leakage, effectively. A CIP cleaning device is available.

5. Film rolling and laminating system

The film rolling and laminating system is composed of film feeding unit and waste collecting device. The film feeding unit contains film reel placing device, film reel pulling and controlling device, photoelectric label inspection apparatus, and film guide roller.

6. Sealing system

Apart from heating and constant temperature control device, the sealing system also includes temperature sensor, rack, cup holding device, heat sealing plate, sealing head, and pneumatic sealing execution unit. The special sealing device supports sealing requirement for hot liquid filling.

7. Cooling device of horizontal form fill and seal machine

The cooling device for the liquid packaging equipment depends on the conditions of the liquid or paste.

8. Punching device

The punching device is made up of the punching mould, fold pressing knife, mold assembly device, gear motor, etc.

9. Electrical control system

For high safety, the electrical control system is installed with PLC system, power supply circuit, electric protection device, failure warning unit, and emergency shutdown system.

10. Pneumatic system

The pneumatic system of the horizontal form fill and seal machine is constructed with filter, reducing valve, lubricator, electrically controlled reversing valve, air pressure protection switch, gas circuit, and connector. In addition, the organic glass screen is optional for high safety and hygiene.

11. Others

The rack, which is covered by stainless steel plate, is made of stainless steel profiles. In addition to the aluminum alloy mould, the moving die for sealing purpose is made of aluminium alloy, as well. The die surface is coated with PTFE to eliminate film sticking. Other assembly component for the horizontal form fill and seal machine is produced from stainless steel or other material conforming to sanitary requirement for foodstuff.

| Model | SKB-6L | SKB-8L | SKB-12L |

| Production Capacity | 30-60 cups/min | 50-75 cups/min | 80-120 cups/min |

| Sealing Film Type | Film reel | Film reel | Film reel |

| Sealing Film Material | Plastic composite material, plastic aluminium composite material, etc. | Plastic composite material, plastic aluminium composite material, etc. | Plastic composite material, plastic aluminium composite material, etc. |

| Power | 30kW | 30kW | 35kW |

| Air Pressure | 0.6MPa | 0.6MPa | 0.6MPa |

| Compressed Air Consumption | 0.8m³/min | 0.8m³/min | 3m³/min |

| Machine Weight | 3000kg | 3000kg | 3000kg |