Cellophane Overwrapping Machine

Request a Quote

LQ-BTB-300A / LQ-BTB-350

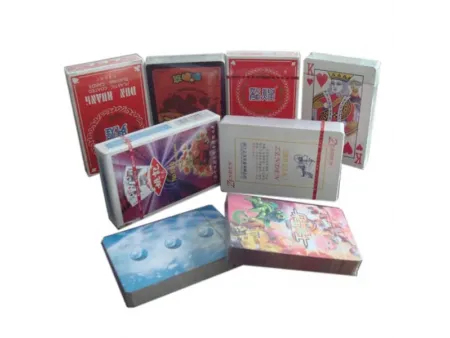

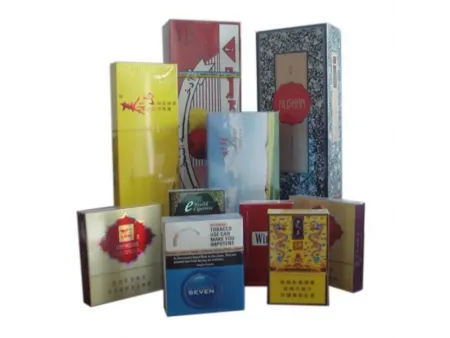

Carton wrapping machine for packaging carton box with BOPP film

This cellophane overwrapping machine is designed to ensure efficient packaging of carton boxes using BOPP film, making it suitable for a range of products, including those in the cosmetics, pharmaceuticals, and food industries. The overwrapper automates the film packaging process and includes a gold tear tape feature, enhancing both the security and appearance of the packaged products. The design of this overwrapping machine incorporates several practical features that make wrapping operations simple and enhance safety without stopping production for adjustments. These features improve the packaging process, ensuring it is not only efficient but also consistent and safe for operators.

Main Components

Specifications

| Model | ||

| Packaging Material | BOPP film and gold tear tape | BOPP film and gold tear tape |

| Packaging Speed | 40-70 packs/min | 30-60 packs/min |

| Max. Package Size | (L)240×(W)120×(H)60mm | (L)300×(W)120×(H)60mm |

| Power Supply | 220V 50Hz 5kW | 220V 50Hz 5kW |

| Weight | 500kg | 600kg |

| Overall Dimensions | 2000×700×1400mm (L×W×H) | (L)2000×(W)800×(H)1400mm |

Features

- Replacing molds is quick and simple, with no need to adjust the height of worktops or to assemble/disassemble material discharge chains and hoppers. This reduces mold replacement time from four hours to just 30 minutes

- Equipped with new double safeguard mechanisms, overwrapper ensures that spare parts remain undamaged even if the wrapping machine runs out of step, without the need to stop the wrapping equipment

- The unilateral hand swing device prevents adverse shaking during operation. Additionally, the hand wheel remains stationary while the wrapping machine is running, ensuring operator safety

- The double-rotary film cutter maintains its sharpness for many years without the need for frequent milling, overcoming the wear issues common with traditional single-rotary cutters