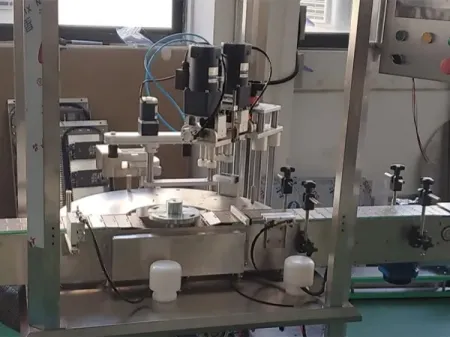

Rotary Capping Machine

Request a Quote

LQ-ZP-400

Screw capper for attaching plastic or metal caps on bottles and containers

The rotary capping machine stands out as a high-performance solution designed to efficiently attach both plastic and metal screw caps onto bottles and containers. Engineered for versatility, this capping equipment is ideal for sectors like cosmetics, food, beverages, pharmaceuticals, and pesticides, accommodating a wide range of bottle shapes and sizes easily. Our rotary capping machines are equipped to integrate smoothly with various parts of the production line; this capper can effortlessly connect with automatic filling systems and electromagnetic sealing machines, enhancing the overall packaging process and increasing the production capacity.

Main Components

Specifications

| Speed | About 30 bottles/min (depending on product size) |

| Qualified Rate | ≥98% |

| Power Supply | 220V, 50Hz, 1Ph, 1.5kW |

| Air Source | 0.4kg/cm2, 10m3/h |

| Machine Size (L×W×H) | 2500mm×2000mm×2000mm |

| Weight | 450kg |

Features

- Equipped with modular capping heads, this screw capper allows for quick changes between different bottle dimensions. Each head is designed for easy swapping, enhancing the process and ensuring a perfect seal every time

- Depending on cap type, users have the choice of using a lifter or a vibration plate to feed caps into the capping machine. Each option is optimized for consistent performance, ensuring caps are always ready for application

- With its precision and ease of use, this capper is a perfect fit for industries ranging from pharmaceuticals to daily chemicals, proving its versatility and reliability in different settings

- Features an advanced cam indexer that ensures flawless positioning without any gaps, leading to more accurate capping and reduced chances of misalignment

- Operators can easily manage settings and monitor operations through a touch screen interface backed by PLC controls. This interaction makes the equipment straightforward to use, reducing training time and enhancing productivity

- This system is smart enough to detect the presence of bottles; if a bottle is missing, it won’t feed a cap or attempt to apply one, saving resources and reducing waste

- The construction includes stainless steel surfaces to meet GMP standards, ensuring that the equipment is both safe and suitable for hygienic processing environments

- Thanks to mechanical transmission, the equipment offers precise and smooth operation with minimal wear and tear. This design ensures stable performance, especially in batch production

- With frequency-controlled drives, the exit speed is adjustable to match various packaging lines, making this machine a flexible choice for different production requirements