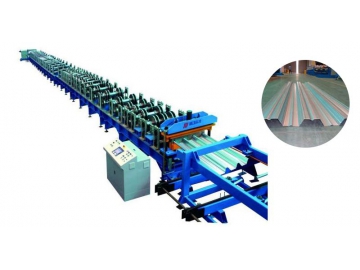

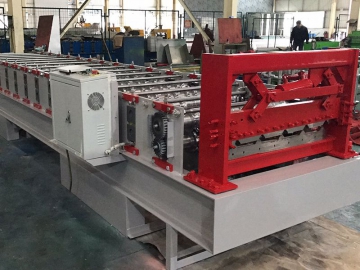

Roll Forming Machine (For Steel Roof Sheets)

As an expert in sheet metal fabrication, we have especially designed the roll forming machine to meet client-side demands on steel roof sheet production.

Technical Data of the Roll Forming Machine| Suitable material | Q235 color steel sheet;0.3-0.7mm, |

| Forming speed | about 20m/min |

| Power Requirement | Main motor power: 7.5 Kw (Depend on final design) |

| Hydraulic station power | 2.2Kw (Depend on final design) |

| Material of forming rollers | No.45 steel, plated with chrome on surface. |

| Material of cutter | Cr12 mould steel with quench treatment, HRC58-60 |

| Material of shaft | High quality 45# steel with heat treatment. Roller grinder milling. |

| Shaft diameter | 72mm |

| Controlling system | Mitsubishi PLC & converter |

| Total weight of machine | About 8500KGS |

| Machine's size | about 15m×1.8m× 1.5m (Depend on final design) |

Advantages of the Roll Forming Machine

1. Through CNC processing and 0.05mm thick chrome plating, the forming rollers for the roll forming equipment offer superior rust resistance and improved precision.

2. Special heat treatment is conducted for the cutting frame to remove the steel stress, thus helping avoid deformation.

3. The cutter blade for the roof panel machine is engineered from Cr12 mould steel and undergoes quenching treatment. Thus long service life is guaranteed.

4. The metal roofing roll forming machine features high precision operation. On one hand, we employ precision CNC machines for the processing of forming rollers. On the other hand, each of the roller shafts undergoes at least twice precision grinding.

5. Mitsubishi PLC with touch screen allows for user friendly man-machine interaction.

6. In addition to premium roll forming machines, we also offer thoughtful customer services. Technician can be sent to your factory to install the machine and train your workers. Lifetime service is available for the metal forming machinery.

-

Roller is made of high grade No.45 forged steel plated with hard chrome, by digital-controlled procession.

-

The cutting blade material is Cr12 with quenched treatment.

Cutting frame has been heat treated to avoid deformation. The tolerance of cutting length is ±2mm.