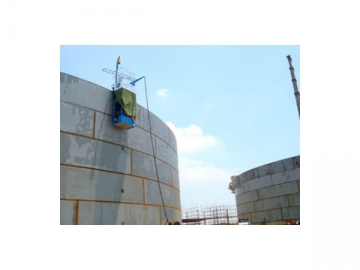

Automatic Girth Welder (AGW)

Seam Welder/ Tank Welder/ Girth Seam Welder

Description of Automatic Girth Welder

Storage tanks are produced in a variety of sizes, shapes and orientations. Our girth seam welding machine is used to provide a secure weld between tank sections in order to produce a tank that will hold together even under working pressures. The tank welder is suitable for any number of different storage tank designs.

Features of Automatic Girth Welder

1. It can realize automatic welding for all girth seams and improve construction efficiency.

2. Suitable for the construction of a wide variety of tanks.

3. Liquid surface of melting pool self-controllable, auto traveling carriage and self-adjustable stick-out.

4. Carriage rail is aluminum alloy structure and magnetically adsorbing, easy to release and fix.

5. Light and compact module.

6. The welding speed is 20 times faster than manual welding.

| Suit tank diameter range | 4.2 meters and above. |

| Tank wall thickness | 6-50mm |

| Suit steel plate height | 1.5m-3.2m |

According to the tank erection method, the machine can be divided into two models. HFHJ-I-Bottom to top and HFHJ-1H, top to bottom.

According to welding efficiency, it can be divided into single sided welding and double sided welding. HFHJ-I & HJFHJ-II.