Medium Frequency Induction Heating Furnace

Main Application:

The medium frequency induction heating furnace is applicable for metal heat treatment prior to forging, extrusion, hot rolling, sintering, tube-bending, tempering, etc. IF equipment has high power capacities and is suitable for heating large workpieces. They cannot be replaced by IGBT solid state IF equipment.

Bar heating

Billet steel heating before rolling

Steel plate heating

Features:

IF heating is one of the most popular and best heating methods for metal materials and has been widely used in fields applying to oil, gas and coal heating. This equipment is highly automated and features great efficiency that you cannot achieve with oil or coal furnaces.

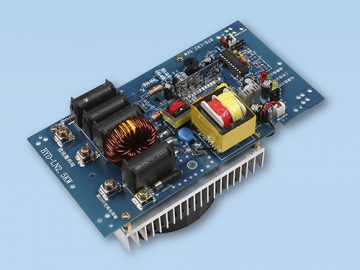

Composition:

The equipment mainly consists of a main cabinet, electric capacitor, induction furnace, transmission device, temperature measuring device, etc. For the automatic type, it also includes a PLC controller, HMI interface or industrial control computer, industrial control software and various sensors.

There are 3 main lining materials: silicon carbide, white fused alumina, and stainless steel. The material is chosen according to the application and the structure of the furnace.