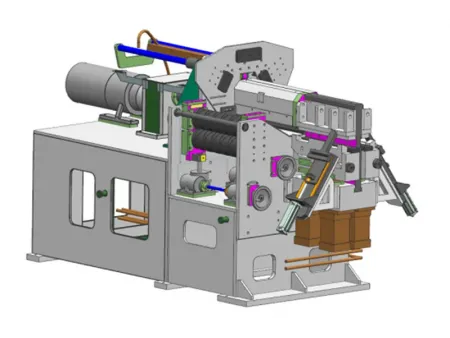

Wheel Rim Coiling Machine with Automatic Loading System

Request a Quote

Equipment

Wheel rim coiler machine used in steel wheel production line to form coiled hoops from flat strips

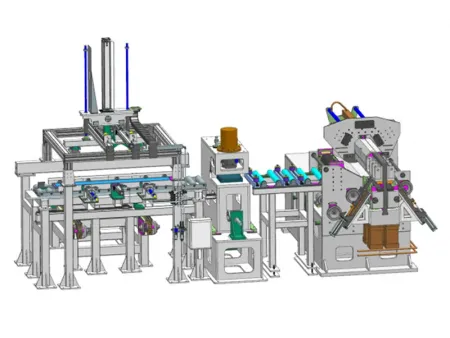

The wheel rim coiling machine is an essential piece of equipment in steel wheel production, designed to form flat steel strips into coiled hoops efficiently. Its automatic loading system optimizes the production of wheel rims by feeding the steel strips into the machine and ejecting coiled rims without manual intervention, reducing labor and improving workflow. This advanced coiling machine integrates three primary components to ensure precision shaping and high productivity: stamping, coiling and flattening.

Component Functions

- The stamping mechanism imprints essential markings onto the raw steel strip, including details like rim specifications, model numbers, manufacturer name, and production date. These marks ensure traceability and quality control across all rims.

- Responsible for forming the steel strip into a circular coiled hoop, the coiling mechanism creates a precise and uniform rim structure that serves as the base for subsequent manufacturing steps of wheel rims.

- After coiling, the flattening system presses the welded joint area, providing a smooth surface that enhances the strength of the final weld, which contributes to a stronger, secure, durable rim structure.

Process Flow Process Flow

- Feeding

- Stamping

- Rim band coiling

- Flattening weld joint

Specifications

| Wheel Types | Passenger Car Wheels | Commercial Vehicle Wheels | Agricultural Vehicle Wheels | Construction Equipment Wheels | |

| Wheel rim diameter | 12-17.5inch | 17.5-24inch | 24-54inch | 20-38inch | |

| Wheel rim thickness | ≤4mm | ≤8mm | ≤9mm | ≤20mm | |

| Wheel rim width | 3-10inch | 5.5-16inch | 7-28inch | 7-28inch | |

| Machine models | Model of coiling machine | QYJ-300 | QYJ-500 | QYJ-600 | QYJ-800 |

| Model of stamping machine | YZJ-300 | YZJ-500 | YZJ-600 | YZJ-800 | |

| Input power | Main spindle power | 11kW | 11kW | 15kW | 22kW |

| Total power | 25kW | 31.5kW | 36.5kW | 45kW | |

| Coiling roller diameter | 124mm | 165mm | 165mm | 200mm | |

| Coiling roller speed | 88r/min | 63r/min | 63r/min | 44r/min | |

| Machine weight | 10T | 12T | 16T | 18T | |

| Max. flattening force | 4*140KN | 4*180KN | 4*180KN | 1000KN | |

| Power supply | AC 380V/3phase/50Hz,customizable | ||||

Features

- The position of the coiler can be conveniently adjusted using a handwheel, allowing for precise customization.

- Equipped with a hydraulic rotary marker , the stamping mechanism ensures clear, attractive markings on the steel strip.

- After coiling, a hydraulic loader automatically ejects the rim, reducing manual handling.

- The integrated lubrication system features an automatic pump for scheduled lubrication, ensuring smooth and consistent operation.

- The coiler bearings are sourced from renowned international brands, providing extended durability and reliable performance.

- Four oversized hydraulic cylinders are used to form flat ends at the end of the rings, ensuring optimum clamping for the welding process.

- Both automatic and manual feeding options are available to meet specific customer requirements.

- By combining the flattening and coiling systems, this design of our wheel rim coiling machine saves space and increases operational efficiency.