Permalloy Ni79Mo4 Magnetic Alloy

View All: http://alloy-material.com

Introduction

Permalloy magnetic alloy is of Fi-Ni alloy with a wide nickel content range of 35%-90%. The biggest characteristic of permalloy is high magnetic permeability of weak magnetic field. And its saturation induction density is generally within 0.6-1.0T.

| Style | Size | ||

| Wire | D= 0.1~8mm | ||

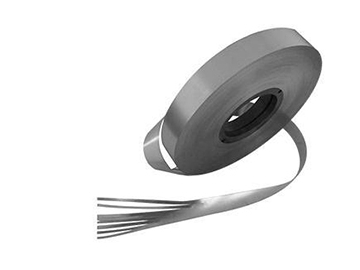

| Strip | W= 8~390mm | T= 0.3mm | |

| Foil | W= 10~100mm | T= 0.01~0.1mm | |

| Rod | Dia= 8~100mm | L= 50~1000mm | |

Application

Permalloy is used in aviation industry and other electronic industries for manufacturing electronic elements with features of high sensitivity, exact size, small size, low high frequency loss, good stability of time and temperature and special function.

| Ni | 78.5~80.0 | Fe | Bal. | Mn | 0.6~1.1 | Si | 0.3~0.5 |

| Mo | 3.8~4.1 | Cu | ≤0.2 | ||||

| C | ≤0.03 | P | ≤0.02 | S | ≤0.02 |

| Yield strength | Tensile Strength | Elongation |

| Mpa | Mpa | % |

| 980 | 1030 | 3~50 |

| Density (g/cm3) | 8.6 |

| Resistivity under 20℃(Ωmm2/m) | 0.55 |

| Linear expansion coefficient (20℃-200℃) X10-6/℃ | 10.3~11.5 |

| Saturation magnetostrictive coefficient, λθ/ 10-6 | 2.0 |

| Curie point, Tc/ ℃ | 450 |

| Initial magnetic permeability | Max.magnetic permeability | Coercive force | Saturation induction intensity | |||||

| Cold rolled strip/sheet material thickness, mm | μ0.08/ (mH/m) | μm/ (mH/m) | Hc/ (A/m) | BS/ T | ||||

| ≥ | ≤ | |||||||

| 0.01 | 17.5 | 87.5 | 5.6 | 0.75 | ||||

| 0.1~0.19 | 25.0 | 162.5 | 2.4 | |||||

| 0.2~0.34 | 28.0 | 225.0 | 1.6 | |||||

| 0.35~1.0 | 30.0 | 250.0 | 1.6 | |||||

| 1.1~2.5 | 27.5 | 225.0 | 1.6 | |||||

| 2.6~3.0 | 26.3 | 187.5 | 2.0 | |||||

| Hard drawn wire Diameter (mm) | ||||||||

| 0.1 mm | 6.3 | 50 | 6.4 | |||||

| Bar Diameter (mm) | ||||||||

| 8-100 mm | 25 | 100 | 3.2 | |||||

| Annealing medium | Dry hydrogen ( dew point is no more than -40℃) or vacuum, and the residual pressure is no more than 0.1Pa |

| Heating temperature and speed | 1100~1150℃ |

| Heat preservation (h) | 3~6 |

| Cooling speed | Be cooled to 600℃ at a speed of 100 ~ 200 ℃/ h, then be quickly cooled to 300℃. |

Index

nickel iron alloy, alloy strip, alloy rod

Related products

Send Message

Other Products

Most Recent

More

Other Products

Videos