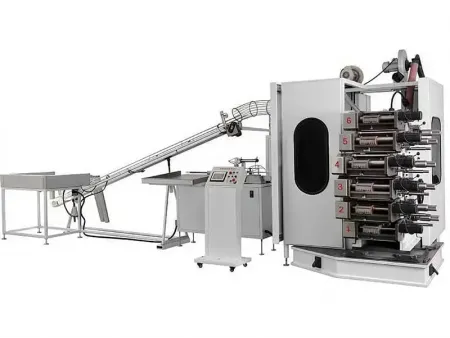

Plastic Cup Printing Machine

This high-performance printing machine is designed for multi-color pattern printing on plastic cups and containers made from PP, PS, PET, PLA, and HDPE. It supports up to 8-color printing with a maximum speed of 330 cups per minute, making it ideal for large-scale production.

The plastic cup printing system is widely used for yogurt cups, ice cream cups, fast-food bowls, beverage cups, and other cylindrical or conical plastic products. It integrates a full automation process including cup feeding, printing, quality inspection, and counting, ensuring efficiency, accuracy, and consistency in every production run.

| Model | |

| Print colors | 4/6/8 colors |

| Max. printing depth | 158mm |

| Cup depth | 50-180mm |

| Cup body slope | 5-12 degree |

| Max. printing speed | 200-330cups/min (depending on cup size and material) |

| Cup material | PP/PS/PET/PLA/HDPE |

| Cup rim diameter | 40-180mm |

| Main motor power (two motors) | 8kW |

| UV curing power | 6kW |

| Total power | 21kW |

| Machine weight | Approx. 5.1t |

| Machine dimensions (L×W×H) | 6200×2500×2660mm |

-

- 1

Automatic incline-type cup feeder, convenient to operate and adaptable for various cup types

-

- 2

Adjustable cup feeding separator ensures smooth and precise transfer into the printer

-

- 3

Roll gearbox with automatic distance adjustment eliminates shadows on the cup surface

-

- 4

Printing plate with specialized punch allows quick alignment and easy operation

-

- 5

Fast and convenient replacement of mold cores or cup molds

-

- 6

Corona inspection system detects defective cups

-

- 7

Sampling inspection function for quality assurance during operation

-

- 8

Servo motor-controlled automatic counting for higher accuracy and easy cup collection

-

For thermoformed cups, the printing machine employs an inclined feed system; for injection-moulded cups, it utilises an upright trapezoidal feed system to ensure smooth and reliable cup conveyance.

-

High-precision feeding system that guarantees stable operation at high speeds, maintaining accuracy and consistency.

-

Printing zone can be adjusted for 1-6 colors based on customer requirements.

-

Pre-corona treatment of the cups before printing to improve ink adhesion and achieve better color quality.

-

Equipped with high-quality SANDEX (Japan) indexing unit, providing long-term durability and reliable performance.

-

Electric witches and controllers from the well-known brand Schneider (France) ensure stability, reliability and safety.

-

Integrated Siemens PLC module for precise and efficient machine control.

-

Every machine is fully assembled and tested before delivery to guarantee performance and reliability.

- ATC-180 6-Color Plastic Cup Printing Machine

- ATC-180 8-Color Plastic Cup Injection Printing Machine