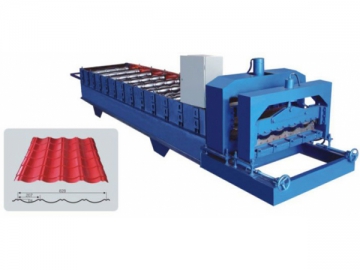

Roll Forming Machine (for Glazed Tile)

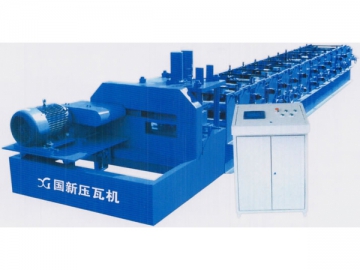

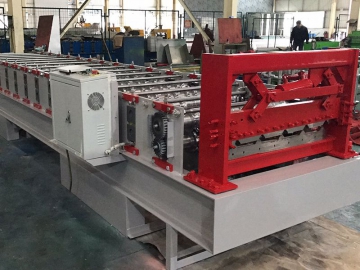

Here at Guoxin, we offer a comprehensive range of roll formers to manufacture glazed metal roof tiles. The metal roofing tile making machines we provide are composed of an uncoiler, feeding device, rollers, a shearing device, hydraulic power pack, and a computer control system. In addition, the optional devices of our roll forming machine include a common uncoiler, hydraulic uncoilder, automatic cutting machine, and more.

The glazed tiles made by the roll forming machine feature a gorgeous appearance and are commonly used for high end construction

Classifications

Technical Parameters

| Dimensions (L × W × H) | 11800mm × 1700mm × 1600mm |

| Roll rows | 14-16 rows |

| Roller material | 45# steel |

| Electroplated coating thickness of roller | 0.05mm |

| Shearing tool material | Cr12 |

| Speed | 0-3m/min |

| Electrical control system | Industrial computer; PLC; variable frequency control |

| Main motor power | 4Kw |

| Power of hydraulic power unit | 3Kw |

| Tile thickness | 0.4-0.6mm |

| Tile expansion width | 1000 mm (Customizable) |

Technical Parameters

| Dimensions (L × W × H) | 10000mm × 1700mm × 1600mm |

| Roll rows | 9-11 rows |

| Roller material | 45# steel |

| Electroplated coating thickness of roller | 0.05mm |

| Shearing tool material | Cr12 |

| Speed | 0-3m/min |

| Electrical control system | Industrial computer; PLC; variable frequency control |

| Main motor power | 3Kw |

| Power of hydraulic power unit | 3Kw |

| Tile thickness | 0.4-0.6mm |

| Tile expansion width | 1000 mm (Customizable) |

Technical Parameters

| Dimensions (L × W × H) | 10000mm × 1700mm × 1600mm |

| Roll rows | 11-12 rows |

| Roller material | 45# steel |

| Electroplated coating thickness of roller | 0.05mm |

| Shearing tool material | Cr12 |

| Speed | 0-3m/min |

| Electrical control system | Industrial computer; PLC; variable frequency control |

| Main motor power | 3-4Kw |

| Power of hydraulic power unit | 3-4Kw |

| Tile thickness | 0.4-0.6mm |

| Tile expansion width | 1000 mm (Customizable) |

Technical Parameters

| Dimensions (L × W × H) | 10000mm × 1700mm × 1600mm |

| Roll rows | 10-11 rows |

| Roller material | 45# steel |

| Electroplated coating thickness of roller | 0.05mm |

| Shearing tool material | Cr12 |

| Speed | 0-3m/min |

| Electrical control system | Industrial computer; PLC; variable frequency control |

| Main motor power | 3Kw |

| Power of hydraulic power unit | 3Kw |

| Tile thickness | 0.4-0.6mm |

| Tile expansion width | 1000 mm (Customizable) |

Technical Parameters

| Dimensions (L × W × H) | 11000mm × 1700mm × 1600mm |

| Roll rows | 11-12 rows |

| Roller material | 45# steel |

| Electroplated coating thickness of roller | 0.05mm |

| Shearing tool material | Cr12 |

| Speed | 0-3m/min |

| Electrical control system | Industrial computer; PLC; variable frequency control |

| Main motor power | 4Kw |

| Power of hydraulic power unit | 4Kw |

| Tile thickness | 0.4-0.6mm |

| Tile expansion width | 1200 mm (Customizable) |

Technical Parameters

| Dimensions (L × W × H) | 11000mm × 1700mm × 1600mm |

| Roll rows | 11-13 rows |

| Roller material | 45# steel |

| Electroplated coating thickness of roller | 0.05mm |

| Shearing tool material | Cr12 |

| Speed | 0-3m/min |

| Electrical control system | Industrial computer; PLC; variable frequency control |

| Main motor power | 4Kw |

| Power of hydraulic power unit | 4Kw |

| Tile thickness | 0.4-0.6mm |

| Tile expansion width | 1250 mm (Customizable) |

As a professional manufacturer of roll former machines for glazed roofing tiles, we also offer 1020mm, 1035mm, 1080mm, 1090mm and 1100mm type glazed tile roll forming machines.