CNC Gear Cutting Machines

- Covers 3-260 mm gear diameters and modules up to 6 mm, with 20 models available

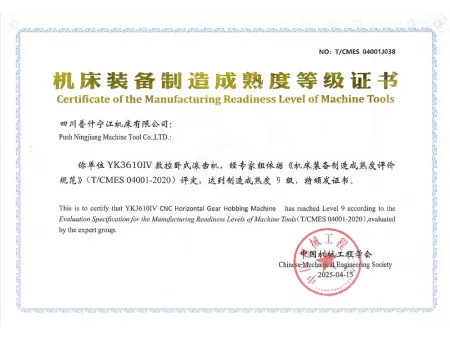

- The YK3610Ⅳ model has reached Level 9 manufacturing maturity, a high level in gear hobbing machine manufacturing

- Holds over 60% market share in China for fine pitch gear hobbing machine

How is stability and tool life improved during high-speed gear machining?

Stability increases when the machine frame has sufficient rigidity, the spindle is dynamically balanced, and high-precision linear guides are used. Using coated carbide tools, setting reasonable cutting parameters, and keeping consistent cooling and lubrication all help reduce wear. When vibration monitoring is available, it supports smoother cutting and helps protect tool life at higher speeds.

What module and diameter range can CNC hobbing machines support?

CNC hobbing machines work with gears in the 0.5 to 4 mm module range and are suitable for diameters from 150 to 260 mm. That basically covers the sizes most workshops deal with when producing small to mid-size gears.

Do CNC gear cutting machines support batch production and rapid model switching?

Machines equipped with the FANUC 31i-B control system allow quick model switching through program adjustments. Continuous generating processes enable efficient high-volume gear machining while maintaining consistent accuracy.

What factors are important when selecting cutting tools for gear machining?

Cutting tools with good hardness and toughness offer better stability during gear machining. Edges that have been reinforced hold up more consistently under load. The tool diameter also needs to match the cutting depth, since tools with an excessive length-to-diameter ratio tend to vibrate and affect accuracy.

How do CNC gear cutting machines perform when machining titanium alloys, particularly regarding rigidity and vibration control?

A high-rigidity machine bed and preloaded ball screws help suppress vibration during titanium alloy machining. Certain models include vibration-monitoring functions that adjust machining parameters in real time to maintain precision.

Can CNC worm-wheel gear grinding machines meet the accuracy standards required for EV reducer gears?

The worm-wheel gear grinders are designed to reach the precision required for EV reducer gears. They use continuous generating grinding, operate with the FANUC 31i-B control system, and work on a seven-axis platform with five-axis interpolation. Gear accuracy reaches GB Class 3, while still maintaining good machining efficiency.