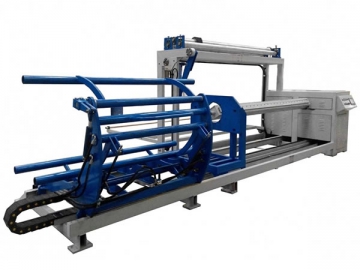

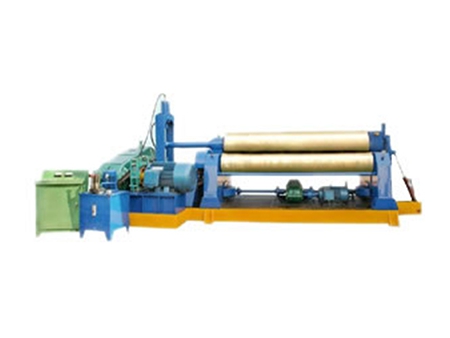

Wire Mesh Rolling Machine

Wire Mesh Machine / Mesh Roller / Wire Roller

The wire mesh rolling machine is used to roll processed mesh into coils that can then be transported and stored with greater ease. Our mesh rollers come in two types: standard mesh rolling machines and automatic mesh rolling and unloading machines.

Main Features of the Standard Mesh Rolling Machine

The standard mesh roller is easy to operate with a manual mesh unloading operation.

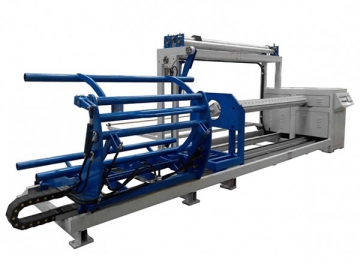

Main Features of the Automatic Mesh Rolling and Unloading Machine

1. It is equipped with sensor that detects and adjusts the rolling speed according to the welding speed, so as to keep the coil at the desired tension.

2. Mesh coil is automatically unloaded after the rolling mesh is finished.

| Model | Standard 2100 | Standard 2500 | Automatic 2500 |

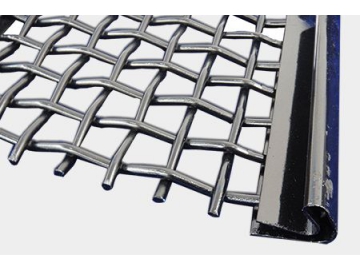

| Wire diameter | 3-6 mm | 3-6 mm | 3-6 mm |

| Wire space | 100 mm | 100 mm | 100 mm |

| Coil external diameter | ≤840 mm | ≤840 mm | ≤840 mm |

| Max. width of mesh | 2100 mm | 2500 mm | 2500 mm |

| Welding speed | 18 r/min | 18 r/min | 16r/min |

| Coil internal diameter | 240 mm | 240 mm | 240 mm |

| Mesh rolling length | ≤50 m | ≤50 m | ≤50 m |

| Mesh weight | ≤670 kg | ≤800 kg | ≤800 kg |

| Rolling motor | 1.5 kw | 1.5 kw | 1.5 kw |

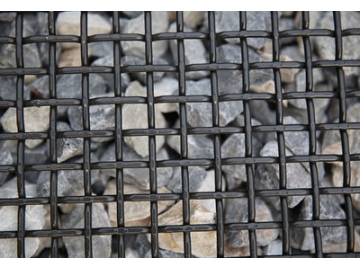

Applications

Mesh rolling machine is used to roll the finished mesh into coils for easy transportation and storage.