Wire Mesh Welding Machine

Welded Mesh Machine / Welding Equipment / Mesh Machine

Features of the Wire Mesh Welding Machine

The wire mesh welding machine is a specialized welding unit with the following characteristics:

1. Both line and cross wires are coil fed into the machine with continuous feeding capabilities.

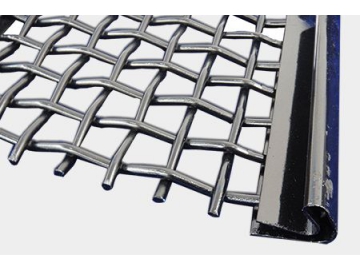

2. The welding process is synchronously controlled with high precision and stability. The welds are solid without burn marks.

3. Both line and cross wires are pulled from the pay-off unit. It is equipped with a precise wire cutting device (Patent No: ZL02208722.2) and an axial locating device (Patent No: ZL02208721.4), making the length of line wires consistent and the edges clean.

4. The mesh pulling system adopts an elastic rod (Patent No: ZL200520024380.9) and mesh size locating device, allowing for adjustment with high accuracy.

5. Welding speed can reach to 80t/min, Only one operator can complete the whole production process.

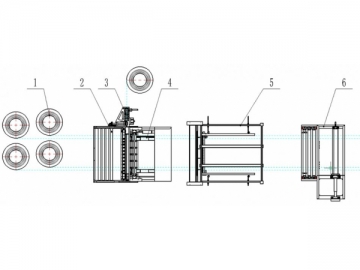

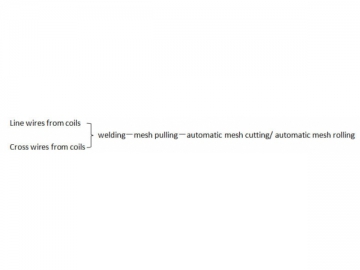

Technological processes of the Wire Mesh Welding Machine Technical Parameters of Wire Mesh Welding Machine

Technical Parameters of Wire Mesh Welding Machine | Model | GWCD1200A (1.5-2.4) | GWCD1200A (1.5-3.0) |

| Wire diameter | 1.5-2.4 mm | 1.5-3.0 mm |

| Quantity of welding spot | 25 | 25 |

| Width of mesh | ≤1200 mm | ≤1200 mm |

| Transverse wire spacing | 50-200 mm | 50-200 mm |

| Longitudinal wire spacing | 50-200 mm | 50-200 mm |

| Min. power | 100KVA | 100KVA |

| Best power | 125 KVA | 315 KVA |

| Welding speed | 60-80t/min | 60-80t/min |

| Control system | SCM | SCM |

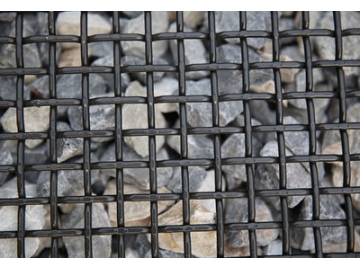

Applications

This equipment is primarily used to manufacture welded wire meshes and underfloor heating meshes. This machine is mainly used to produce welded wire meshes and underfloor heating meshes.