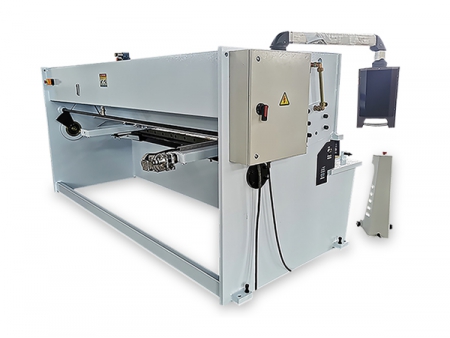

Swing Beam Shearing Machine QC12Y

Swing beam shears are metalworking equipment designed to cut and process sheet metal precisely and efficiently. By securely holding the steel plate in place, these shearing machines use the relative motion between the upper and lower blades to exert shearing force, allowing for accurate cutting of metals of various thicknesses. Engineered to be versatile, they accommodate a broad range of metal materials, including steel and aluminum, ensuring stable cutting conditions and improved accuracy. Their design minimizes blade deflection, enhancing the cut's precision, making them indispensable for high-quality metal fabrication.

Being a key component of metalworking machinery, swing beam shears are indispensable in fields such as construction material processing, shipbuilding plate processing, and manufacturing automotive components. They efficiently meet the cutting demands of multiple sectors, demonstrating their versatility and essential role in industrial manufacturing.

| Model | Max. shearing thickness | Max. shearing width | Distance between uprights | Working table height | Strokes | Back gauge stroke | Shearing angle | Throat depth | Main power | Dimensions (L×W×H) |

| mm | mm | mm | mm | Min-1 | mm | ° | mm | kw | mm | |

| | 4 | 2000 | 2150 | 740 | 20 | 20-550 | 1°30' | 100 | 4 | 2500×1600×1550 |

| | 4 | 2500 | 2700 | 740 | 18 | 20-550 | 1°30' | 100 | 4 | 3100×1600×1550 |

| | 4 | 3200 | 3410 | 800 | 14 | 20-550 | 1°30' | 150 | 4 | 3800×1700×1650 |

| | 4 | 4000 | 4220 | 800 | 10 | 20-550 | 1°30' | 150 | 5.5 | 4650×1900×1750 |

| | 4 | 4500 | 4720 | 800 | 8 | 20-550 | 1°30' | 150 | 5.5 | 5150×1900×1750 |

| | 6 | 1500 | 1660 | 780 | 20 | 20-550 | 1°30' | 150 | 7.5 | 2000×1760×1650 |

| | 6 | 2500 | 2720 | 780 | 17 | 20-550 | 1°30' | 150 | 7.5 | 3100×1650×1600 |

| | 6 | 3200 | 3420 | 800 | 14 | 20-550 | 1°30' | 150 | 7.5 | 3800×1750×1650 |

| | 6 | 4000 | 4220 | 800 | 10 | 20-550 | 1°30' | 150 | 7.5 | 4650×1850×1750 |

| | 8 | 1500 | 1660 | 800 | 20 | 20-550 | 1°30' | 150 | 7.5 | 2000×1860×1750 |

| | 8 | 2500 | 2720 | 800 | 14 | 20-550 | 1°30' | 150 | 11 | 3100×1750×1700 |

| | 8 | 3200 | 3440 | 800 | 10 | 20-550 | 1°30' | 150 | 11 | 3800×1850×1750 |

| | 8 | 4000 | 4230 | 800 | 8 | 20-550 | 1°30' | 150 | 11 | 4600×1900×1800 |

| | 8 | 1500 | 1660 | 800 | 20 | 20-550 | 1°30' | 150 | 11 | 2100×1860×1800 |

| | 10 | 2500 | 2720 | 800 | 12 | 20-550 | 1°30' | 150 | 11 | 3100×1750×1700 |

| | 10 | 3200 | 3440 | 800 | 10 | 20-550 | 1°30' | 150 | 11 | 3800×1850×1750 |

| | 10 | 4000 | 4230 | 800 | 8 | 20-550 | 1°30' | 150 | 11 | 4600×1900×1800 |

| | 12 | 1500 | 1680 | 800 | 14 | 20-550 | 2°9' | 150 | 15 | 2200×2000×1850 |

| | 12 | 2500 | 2760 | 810 | 10 | 20-750 | 1°50' | 150 | 15 | 3200×2000×1850 |

| | 12 | 3200 | 3465 | 810 | 10 | 20-750 | 1°45' | 150 | 22 | 3850×2150×2000 |

| | 12 | 4000 | 4265 | 810 | 7 | 20-750 | 2° | 150 | 22 | 4700×2300×2100 |

| | 16 | 1500 | 1680 | 800 | 10 | 20-550 | 2°30' | 150 | 22 | 2600×1950×1800 |

| | 16 | 2500 | 2765 | 850 | 8 | 20-750 | 2°9' | 150 | 22 | 3200×2150×2050 |

| | 16 | 3200 | 3455 | 860 | 7 | 20-750 | 2°9' | 150 | 22 | 4000×2300×2150 |

| | 16 | 4000 | 4285 | 900 | 6 | 20-750 | 2°9' | 150 | 22 | 4850×2500×2350 |

| | 20 | 2500 | 2815 | 860 | 6 | 20-750 | 2°30' | 150 | 30 | 3450×2350×2200 |

| | 20 | 3200 | 3487 | 890 | 5 | 20-750 | 2°30' | 150 | 30 | 4050×2450×2250 |

| | 20 | 4000 | 4305 | 990 | 5 | 20-750 | 2°20' | 150 | 30 | 4900×2300×2450 |

| | 25 | 2500 | 2805 | 900 | 5 | 20-750 | 3°7' | 150 | 37 | 3450×2500×2350 |

| | 25 | 3200 | 3505 | 900 | 5 | 20-1000 | 3°7' | 150 | 37 | 4160×2600×2500 |

| | 30 | 2500 | 2825 | 900 | 4 | 20-1000 | 3°12' | 200 | 45 | 3500×2650×2500 |

| | 30 | 3200 | 3450 | 1000 | 4 | 20-1000 | 3°12' | 200 | 45 | 4350×3050×2800 |

- High production efficiency: Capable of fast and efficient cutting, making it ideal for processing big volumes of metal sheets.

- Energy-efficient performance: Features an electro-hydraulic proportional regulation system to ensure precise oil supply, reducing energy consumption.

- Precise metal sheet cutting: Ensures high accuracy and clean cutting edges, producing exceptional quality in finished products.

- Versatile functionality: The swing beam shear can handle various metal sheet materials, meeting a wide range of cutting requirements.

- Automated operation: Equipped with an advanced control system for simple operation by pressing one button, minimizing the need for human intervention.

- Eco-friendly design: Designed to consume less energy while keeping noise and vibration to a minimum, aligning with modern manufacturing's green standards.

- Durable structure: Manufactured with high-quality materials and precision engineering, ensuring a long service life.