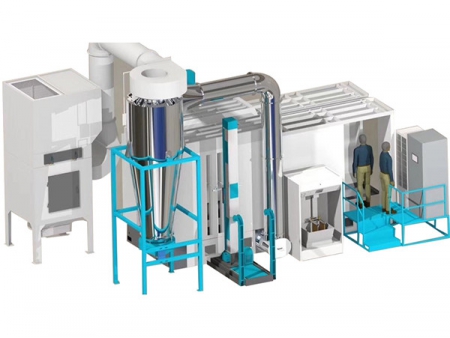

Fast Color Change Powder Coating Spray Booth

Request a Quote

Features

- Automatic powder coating booth with mono cyclone supports fast and contamination-free color change.

- This automatic spray booth is ideal for improved finish quality and enhanced production.

- Booth materials can be customized, available with powder coated steel, stainless steel and plastic material.

- Working with powder feed center achieves fully automatic powder supply and recovery.

- Mono cyclone powder booth is recommended to install at a workshop whose height should be more than 5 meters.

| Operating Dimensions | 800 width x 6000 depth x 2000 height mm |

| Weight | 4000 kg |

| Power supply | Electric |

| Nominal power | 5.5 kW |

| Voltage | 380V/220V |

| Frequency | 50-60Hz |

| Filters | Polyester |

| Filter quantity | 16 pcs |

| Hang type filters | Easy for change |

| Filter cleaning system | Pneumatic |

Cyclone Recovery Unit

- Mono cyclone is the primary recovery stage that maximizes powder recovery up to 98%.

- Mono cyclone design makes the color change in a shorter time.

Cartridge Filter Stage

Cartridge filters stage ensures to fully separate ultra-fine powders from airflow, allowing for the return of clean filtered air back into the coating area.

Self-cleaning System

Booth floor is designed with self-cleaning system. The air cleaning system effectively cleans powder accumulation from booth floor and pushes it to the cyclone recovery system.

Automatic Coating Station

It’s engineered for reciprocators and automatic spray guns to achieve large scale continuous powder coating production.

Manual Coating Station

An open-face coating station provides more convenience for simple coating inspection or manual touch up.

Related Names

Powder Coating Room | Powder Coating Booth | Powder Coating Painting Booth | Powder Coating System | Powder Coating Workstation